General motors 24X trigger system

Configuration: "LS1 forgiving bit" enabled

See [VT help] for more info on operation of "LS1 forgiving"

[1.1.91 benchtested config] with 48+1 trigger (type c048 in VT Tools/Play Trigger) and

- HALL-type primary trigger only !

- in case of LS1, primtrig falling edge selected (which is spaced evenly every 15 crankdegrees)

- secondary_trigger=1C "LS1 forgiving bit" enabled

- bit2=1 (was called filtering earlier but actually was unused for sectrig, now "LS1 forgiving")

Note that the "LS1 forgiving" = disabled is still the recommended default setting if the campulse can be placed sufficiently far from the primtrig chosen edge. Normally this can be achieved even with a 24+1 trigger, and often also with a 48+1 LS1 (other LS1 trigger engines operated that way earlier).

Background

This trigger is used on the very popular LS1, LS6 engine and many other V8 engines in this engine family. All these engines are popular to retrofit in cars as it is very light and weigh less then many four cylinder engines. We should try to support it properly.

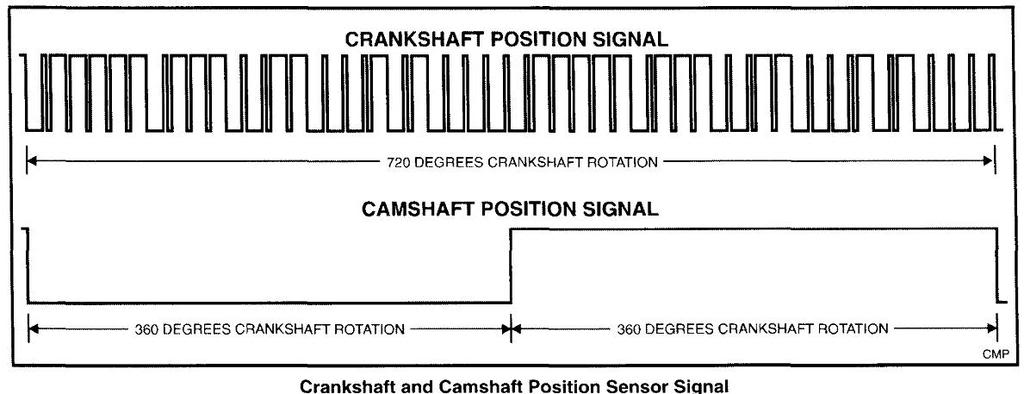

It is very hard to modify the secondary trigger angle on these engines to get it exactly between the primary trigger pulses.

Problem (without "LS1 forgiving")

It works fine on 48+1 trigger on most cars. The cam sync trigger is however a bit too close to the primary trigger pulses and it sometimes cause a race condition. This seem to have become worse on 1.1.88 compared to the results seen on 1.1.76.

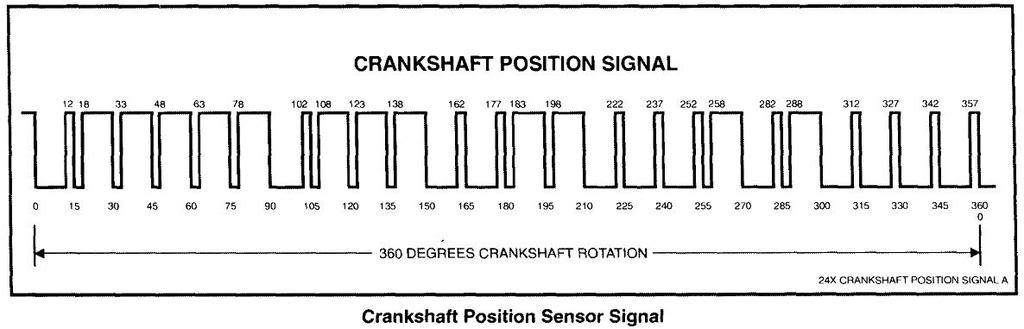

The primary trigger has 24 pulses per revolution where the falling edge of the trigger signal is at 15 deg intervals and the pulse length of the logical '0' is 12 or 3 degrees. As the pulse density is high and the difference is fairly large I think that we can detect this reliably even when cranking. The sync is possible in 90 deg.

Trigger Pattern

The 24X trigger pattern look like this:

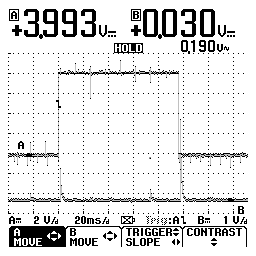

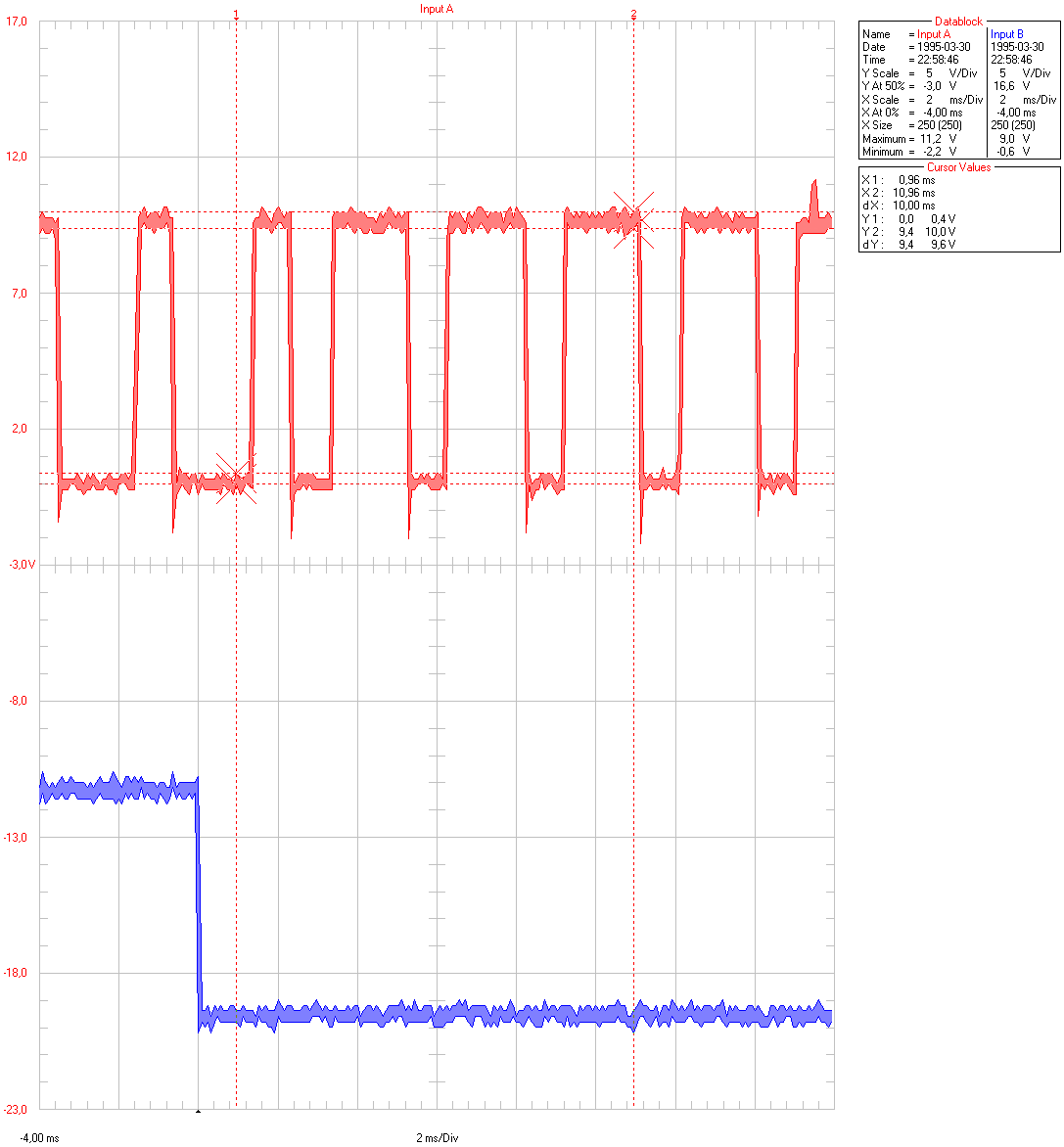

Scope captures around #1 TDC:

The capture above show the spark from #1 together with the cam sync. This was taken with the timing locked at 1deg. Ignore the noisy signals, I used a chassi ground for the scope. I only took this to verify the timing of the cam sync sensor

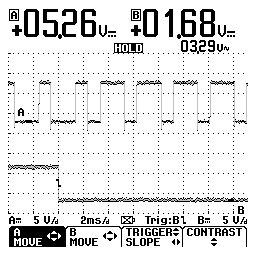

This how how the primary and secondary trigger signals look around #1 TDC. Bigger version of the same is found here:

Trigger log and a short normal log is found here, Primary=falling edge, Secondary=falling edge. Bad sec trig position shows up around 1 minute in the log:

http://www.vems.hu/files/JorgenKarlsson/24X/Peter_Cab-2465.zip

The pattern can be broken down to this:\nÿ1ÿ

If I only specify the length of the logical '0' we get:

0deg to 90deg:

12,3,3,3,3,3

90deg to 180deg:

12,3,3,3,12,12

180deg to 270deg:

3,3,12,12,12,3

270deg to 360deg:

12,3,12,12,12,12

The cam sync has a 360 crank degree duration and will change from 0 to 1 or 1 to 0 around 0 crank degrees. The spec sheet say that it should do it at 0 deg but in reality it occur a few degrees from the previous falling edge of the primary trigger. At least of the engines I have run a trigger log on.

Div-by-N

Auditrigger (traditionally divby3, that would be tooth count=16 in this case) always allowed 1 tooth sloppiness in the sectrig.

- Emil shared a [divby2 config] (tooth count=24) which was working for him earlier on LS1 engine.

- theoretically divby 6 (tooth count=8) would be an option too

Trigger-detection with sectring LS1 forgiving bit - implemented

From 1.1.91 secondary_trigger bit2=1 ("LS1 forgiving"=enabled)

- this bit was possible to set with old VT ini:

- sectrig filtering=enabled (but filtering for sectrig actually made no effect in older firmwares).

It may be useful for 24+1 (c024) type triggers also. But the recommendation remains:

- to have sectrig pulse always between 2 certain primary trigger pulses, and the LS1 forgiving bit disabled.

Yet another solution postponed for now:

- there is some brainstorming about a somewhat error-prone user-configurable campos threshold

- that might be the only solution for lazy-installers on 24+1 (eg. 12 cranktooth) if the campulse is not at the proper factory position (like in Nissan and Toyota), but at some wrong position (which should not actually happen since if it's a homemade setup, it should be 12-1 or 12-2 missing tooth instead of 12 "coiltype" evenly placed pulses, as in a missingtooth setup the camsync position is not sensitive)

This engine family also use a trigger type called 58X which is what other manufacturers call a 60-2 trigger wheel. For example the LS2 engine use this trigger.