VEMS install on 90 degree V2 Honda engine

The engine started (with factory trigger)

- please upload that config.

- However, the engine does not start easily (it should, because this is a motorbike). Needs more investigation.

- Also, at sudden transients trigger error appeared ( and loss of power).

- so the installer changed cam-wheel to 16-1 (so that crank/cam race condition cannot happen). This engine has proper gear-driven camshaft anyway (not belt).

16-1 on cam - since this engine has a proper gear driven camshaft (not a sloppy belt), the camwheel without crankwheel is perfect.

[Settings] for 16-1 wheel on cam

- tooth width=45 deg

- next trigger tooth=2 (which gives 90 degree)

- 8 cyl (even if only 2 cylinders are actually used)

- output 2 and 3 are actual outputs, 4,5,6, 4,5,6 are not actually connected (to anything)

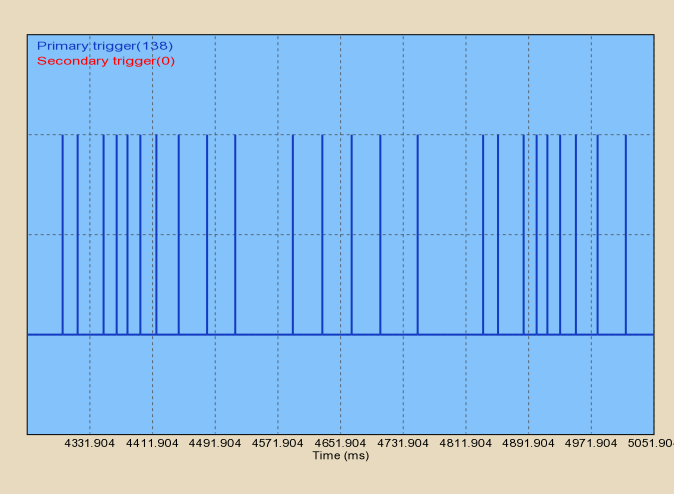

Triggerlog needed - upload the triggerlog

- with both rising and falling edge for HALL primary trigger

- if both crank and camsync are HALL than this is 2*2=4 combinations

90 degree V2 overview

- same as an 8cyl, just 6 cylinders are missing

- honda vtr sp2.V90

- ecu: VEMS v3 firmware 1.1.81 serial no:3410.

- angle between cylinders is: 315 and 405 crankdeg (360-45, 360+45)

- !

- factory ignadv 15 crankdeg

- intake valve opens 20 crankdeg BTDC

'''Trigger almost 16-1 type activ hall jeladÃģval

While it commands sparks perfectly without sparkplugs, with sparks the RPM-changes are extreme (during cranking):

Please upload the triggerlog (captured with sparkplugs) so we can analyze properly ! From gimp measurements it seems:

- 66/38 = 1.7368

- 57/27 = 2.1111

- so around 180-190 % threshold might be good.'

- trigger timing: tdc after the trigger 121 deg.

'Pattern:

- ??? degrees (15 is best, 10-20 can be acceptable)

- We want to help by verifying this, that is why the triggerlog is required

- we assume 15 crankdeg distance here

- cyl2 TDC cyl_1

- assumed 450 deg after cyl1 TDC, assuming 429 deg after crankpulse0 (429=450-15-6)

- if in actuality 270

Proposed config

- toothwidth=45 degree

- because this is crankdegree (22.5deg is WRONG)

- next trigger tooth=2

- trigger tooth =0 (which is 0 deg.)

- Change it to 1 if the "TDC after trigger" is more than 127, and subtract 45 from "TDC after the trigger" value

- TDC after the trigger: 121deg

- with above settings, TDC points come 69 + N *90 deg after crankpulse0

- the existing cylinder cyl2 is at 69 + 4*90 (=429)

- the existing cylinder cyl1 is at 69 + 7*90 (=699)

Ki kell javÃtani mert nem egyÃĐrtelmű ! Egy adott ponthoz (ÃĄltalÃĄban cyl1 TDC) kell mÃĐrni minden esemÃĐnyt/pulzust főtengely-fokban !

- az 1 henger alsÃģ holtpontjÃĄnÃĄl ad jelet illetve a 2es henger alsÃģ holtpontjÃĄnÃĄl is.

- mert a cam sync jeladÃģn kÃĐt jel van 1 tÞske ÃĐs vele szemben (???) 2 tÞske.

- 1. tÞske: 90 BTDC cyl1

injektorok:

- hengerekkÃĐnt 2 injektor van a fojto szelep utÃĄn egymÃĄssal szemben ezeket pÃĄrhuzamosan kÃķtÃķttem mert Ãkos azt mondta elbÃrja (magas inpedenciÃĄs inj)kapcsolt plusz ÃĐs negatÃv

- EC36/7 cyl 1

- EC36/19 cyl 2

Sensors

- BekÃķtve a wbo2 ÃĐs kalibrÃĄlva

- tps kalibrÃĄlva

- vÃz ÃĐs a levego is kÃĐsz

- egt kalibrÃĄlva

- map kalibrÃĄlva

--

Actuators

- Coolant fan now working start - connected s259 5 inverted

- for this special "8 cylinder" (with 6 cyl missing) we recommend to use a stepper output (or any non-injector output) for the coolant relay.

- If we want to time injection without -45 +45 degree cheating, we want to configure all 8 channels for inj - therefore no injector outputs available for other purpose

ALS

- majd mÃĐg szeretnÃĐnk ALS is 10fokos fojtÃģval max 5500 rpm ig..

Ignition outputs maximum 185rpm inditÃģzÃĄs kÃķzben. Ha a gyertyÃĄk benne vannak a motorba akkor trigger erort ir (nincs szikra se)

Passive or active ignition transformers ?

- ignition now connecting ecu36 pin36 pin34

- 0 and 1 seems unfortunate choice for ignout:

- for passive transformers we recommend EC36/34 and EC36/36 (ignchannel 2 and 3) because those are also available in the 2-IGBT version ! See [ignout] (also referred from [assembled controller in webshop] )

- Our proposed initial config assumes ignchannel 2 (cyl2) and 3 (cyl1) ign outputs are used - but easy to change if you know what you are doing

- for active coils ignchannel 4 and 5 makes sense so available even in the 6 IGBT version

- with these recommendations the widest set of controllers (any 2-6 IGBT) ECU will be suitable

Test config

- tested config with 1 tooth coil: http://www.vems.hu/files/MembersPage/HondaV2/v3.3_u001212-A-2011.03.16-12.09.16.vemscfg

- configured:

- primary and secondary trigger,

- trigger tooth table

- inj and ign outputs

- all other will check and set

contact 06 30 276 75 75.

tÃķlstd ki a helyÃĐn a kÃĐrdÃĐseket (ne az aljÃĄra irj, hanem mindent abba a rÃĐszbe ahova tartozik)