Using Vemstune 1.3.1 ,VEMS 3.6 (written on the order receipt and mainboard) but Vemstune recognise it like v3.3 (firmware and bootloader is same for all, so that is OK), firmware 1.2.2.

Engine code: S50B32

Specs:

- 6 cylinder in line

- Infinite variable camshaft angle on both intake and exhaust(VANOS)

- displacement (cm3): 3201

- Stock pistons&rods , 3.5mm Cometic Headgasket and ARP hardware

- Coil on plugs and full sequential

- Stock cams

- Precision Turbo 6262turbo

- 3 vr sensors

- Crank 60-2 = primtrig

- Exhaust 6+1 Sectrig !

- Intake 6 Third trig !

- Dual Vanos Enabled

Started the engine in stock form, nothing changed, i only attached my ecu adapter socket to the car's original ecu socket.

I wanted , for the start to verify vanos functionality.

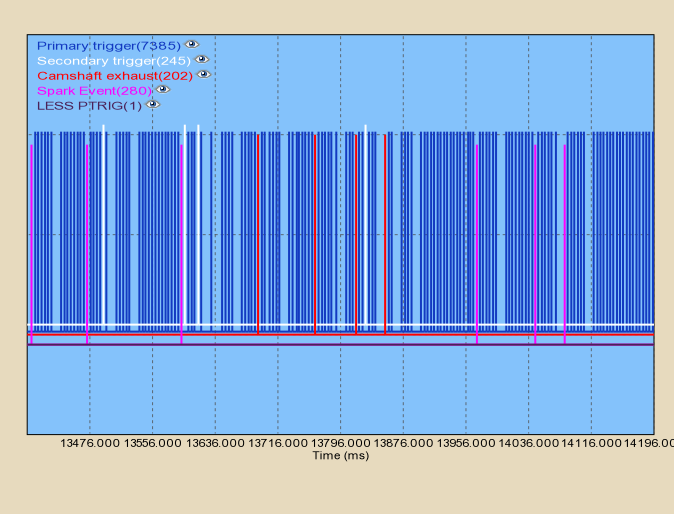

I have problems in getting a stable secondary and third trigger, also, secondary and third triggers tries to follow target cam advance maps, but not with very good success. I have manually put cams in max advance and retard position , and took note of them, after that i have made cam target maps.I have attached leds to solenoid outputs, and they are very unstable, even if in close proximity of cam target. I suspect an unstable trigger signals.

I attach two trigger logs, one only cranking and one at idle, a config file, and a log.

In the Vemslog you will see also, that around 1800-2000 rpm, i have very nasty fuelcut, i don't know the cause.

Use higher baudrate, like 115200 in triggerlog to raise the max RPM where it can capture all pulses

- even then it is limited to about 3-4000 pulses / second, so it won't capture all at high RPM: the exact RPM depends on trigger pattern

- This is a limitation of the serial baudrate (but it's perfect for starting problems and mostly also for idle if used with the right settings - hopefully your serialport handles 115200 baud, most serialport handles it OK).

-

was apparently captured in 19200 baud (where max RPM is ~600 with a 60-2 wheel)

was apparently captured in 19200 baud (where max RPM is ~600 with a 60-2 wheel)- in 115200 baud max RPM is several times higher

I am not very sure about VR sensors polarity, i have tried everything, and i do not have a osciloscope to verify them.

- oscilloscope scopeshot would be highly preferrably (a borrowed scope would save a lot of time) but at least try to "pull away metal from the sensor" if possible, measured polarity should be MINUS (DVM-DC voltage 200mV mode, black probe is the ground).

- For all 3 sensors !

Also a have seen in a DTA wiring instructions, that the Crank and exhaust cam (secondary trigger for vems) has the same polarity, but the intake cam sensor (third trigger) has inverse polarity. Can anyone confirm me that?

- When Marcell started to inspect an S50B32 (with which the main problem later turned out to be a torn crankwheel dampener resulting in trigger error and power-cut around 6800 RPM) only one of the intake or exhaust had to be inverted (but the number of previous inversions applied by the installer since the factory setup was unknown).

- to avoid any uncertainty, polarity of all 3 VR sensors should be verified individually