VEMS Round with Motronic 7.1

VEMS Round using the following input:

- WBO2

- EGT

- Analog 1 --> 10 bar oil pressure sensor

Q: Can't get my head round calibrating this. Can I have some help please with the configuration for analog input. The sensor is linear.

Calibration from vendor:

Sensor Output

150 PSI Gauge 0.5 volts at 0 PSI gauge pressure

(atmospheric pressure)

4.5 volts at 150 PSI gauge pressure

(150 PSI above atmospheric pressure)

150 psi sensor: pressure = 37.5 * voltage - 18.75

Any way to display in bar?

Q: 0.5V=0PSI=0bar, 4.5V=150PSI=10.34bar, with the AnalogInputCalibrationWizard, I get calibration 129, offset 12. Correct?

- As we talked about this in person I would like to add that zeroing out the first 2 values of the curve is not a good idea because it will interfere with the slot button (it will not allow pressing).

- Analog 2 --> 400kPa VEMS Map sensor

- Apparently there is no way to display *BOTH* analog outputs on the display. I would like to see both boost and oil pressure on the slots.

- Very outdated information. If you need to display both analog inputs on the round display at the same time, just use the latest round fw (and in VT Preferences, update ini files from web, of course) and [read VT help]. Support for ANALOG2 on display was added a long time ago.

- Latest nightly VT only supports using ANALOG2 in Display Mode, Main Display Settings do not have ANALOG2 at all and if we configure ANALOG2 in display mode, the main display settings show an empty string in the dropdown.

Outputs:

- PWM0 -> reference RPM drive warning led for shiftlight

- PWM4 -> reference RPM drive "shift-now" led for shiftlight

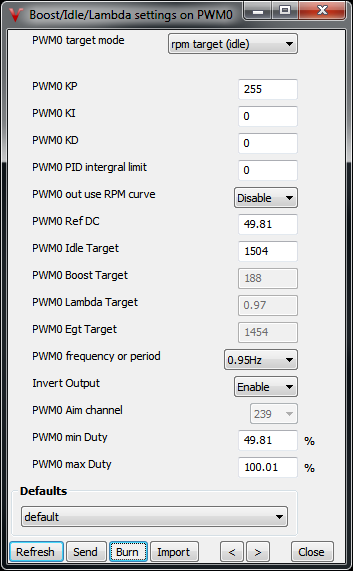

- Example settings for blinking shift-light on PWM0 engaging at 1502rpm, blinking 0.95Hz

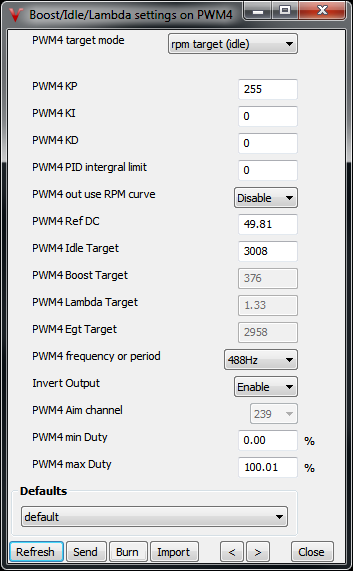

- Example settings for normal shift-light on PWM4 engaging at 3008rpm

Q: The above settings do not work. Nothing happens. PWM0 set to rpm target (idle) and reference rpm dc, duty cycle set to 100% all across the board. LED works fine if I invert the output for testing.

A: Provided elaborated settings above (tested).

- Tested the settings above and they work fine except for the fact that the maximum target idle rpm that can be configured is ~4030. Please either modify the ini files or the firmware, I don't know where the limit is set. Thanks.

- Linear wideband output is connected to Motronic 7.1 for data-logging. (This Motronic ECU is dual-narrowband with dual EGTs for mixture preparation.)

- vout_conf=5 and conversion configured in Motronic as advertised on the AfreshTiny/VoltageOutput page:

5V -> 20 AFR

To calculate the factor, we first must remove the offset. We do this by subtracting the value at 0v from the value at 5v.

20-10=10

This number is the value at 5v without the offset applied. To get the value per voltage we just divide this by 5 (volts).

10/5=2

Our factor is 2 and the offset (value at 0v) is 10.

Now we just apply the factor for the particular RAM variable that we are working with in ME7.

uushk_w voltage factor is 0.004883, so we multiply this by the voltage to AFR factor that we calculated for our new input.

0.004883*2=0.009766

ME7Logger applies a negative offset, so in order to use a positive offset we just need to flip the sign.

The values that we have been working with are AFR, therefore to convert our input to AFR:

Factor : 0.009766

Offset : -10

- RPM input is coming from the Motronic RPM signal (instrument cluster)

Q: Can this even be configured or do we need a crank signal?! If that's the case the documentation (Help) should be change to state something other than "RPM Signal".

A: Yes RPM signal from dash is fully supported, [more info in VT help Rpm Input], example for 4cyl: rpm_toothcount=02 for a 4 cyl 2 events per rotation

Q: Any pointers on configuring it for 6 cyl 4stroke V6 engine? Setting it to 60-2 wheel does not work obviously. Thanks

A: For 6cyl 4 stroke, 6 rpm events per cam rotation, 3 per crank rotation the correct rpm_toothcount=03

Q: With above settings it is not working properly still, vemslog available at: http://nerd.hu/r2.1_4513-2015.04.02-12.42.18.vemslog