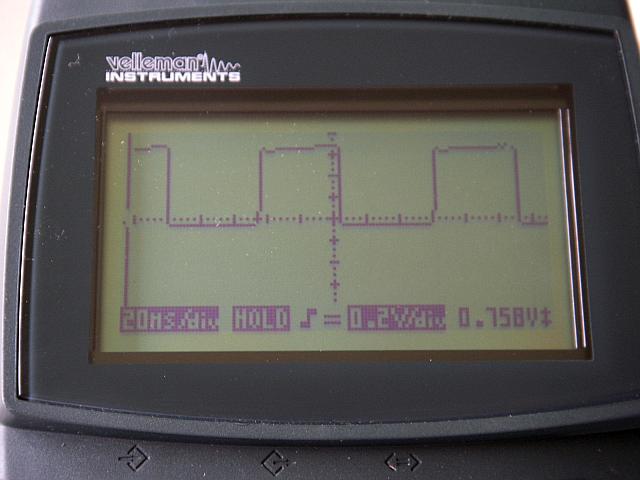

First thing to address is the trigger. The signal is taken from the Jacobs + distributor trigger, and here's the 0.76 Volt square-wave signal:

How to read this safely?

0.76V is a bit too low for a HALL setup. It might work, with some experimentation:

- try a stronger pullup and a voltage divider:

- distributor_signal (the above scopeshot) - 270 Ohm - (ECM HALL input connected here) - 1k Ohm - +5V (EC38pin28)

If this does not help (try to play with the values, eg. try several values from 680 Ohm to 4k7 instead of the 1k resistor).

Shaping the signal with active components (transistor, inverter, amplifier) is probably not justified.

VR setup

VR does not require high amplitude, but requires the signal to go under 0V. A series cap is necessary. Min 10uF 25V

- eg. the 1210 size cap in the GenBoard/VerThree/RescueKit could work

- or a bigger throughole

- or several capacitors in parallel.

Result of VR test

With no cap installed, and the engine still, the ECU reads many thousands of RPM (it varies) and triggers the injectors. With a 10K electrolytic cap in series it seems to read OK when triggered manually (opening the points rapidly with a screwdriver) BUT afterwards when stopped with ignition on, the ECU again reads many thousands of RPM and fires the injectors.

- Anyone got ideas, or should I try the Hall approach instead (means soldering the ECU again :( )?

- document the history of the ECM.

- version

- serialnr

- What did you install (eg. R181 ?)

- LM1815pin5 ? (adaptive hysteresis)

- photo

- firmware

- config (the simple coil-type trigger is more prone to noise than multitooth, especially with the advanced multitooth filter)

- tables

- document the history of the ECM.