- Need help for setting up 36-1 trigger

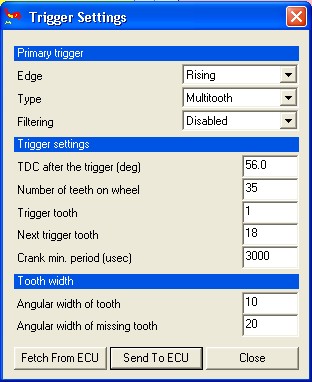

Edge = rising

Type = multitooth

Filtering = Disabled

TDC after the trigger (vr sensor) deg =??

Number of teeth on the wheel = 35

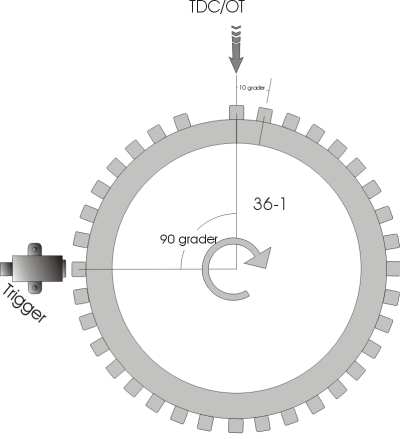

36-1

Trigger tooth = 1

Number one tooth after the missing one

Next Trigger tooth = 18

Crank min period usec = 3000 (assuming a 4cyl that is 6000usec for a whole crank rotation, which is 10000 RPM), but set it lower to be sure.

- reset_engphase_after=decimal 216 (which is an arbitrary number for 720 crankdegrees, practical for 36 tooth wheel). The values below are in the same unit:

- Angular width of tooth = 3 (10 degrees)

- Angular width of missing tooth = 6 (20 degrees)

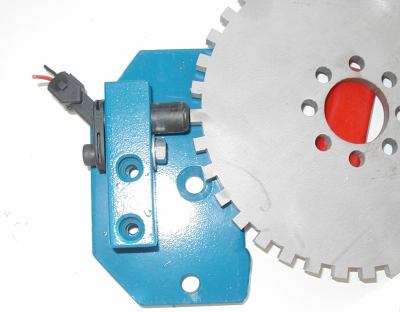

With this non-standard missing-tooth shape, the signal will be bigger aroudn the missing tooth, and R181 (factory-installed on v3.3 ; needs a small and clean tracecut surgery before v3.3) becomes important (min 100k, maybe 180k or higher). See InputTrigger/RunOut

I'd

- measure the signal (record with notebook audio input)

- make a wav-file with slightly even peakier missing-tooth amplitude

- this way check if the setup has the margin for the trigger signal processing.

It's very annoying if the system is near the operation edge, and sometime loses track. In any case, watch wheel-error (mlp01 first line) in case of any hazard.