| [Start] | [Questions ] | [ Injector] | [Ignition] | [Triger] | [Display] | [Wbo2] | [Config] | [Table] |

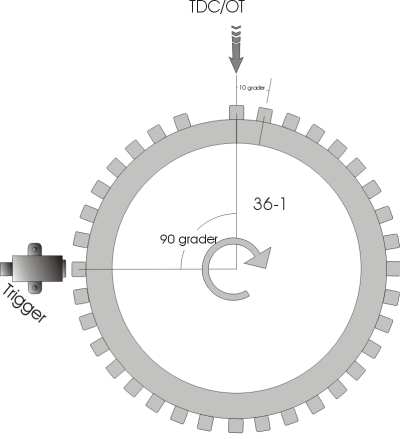

- Need help for setting up 36-1 trigger

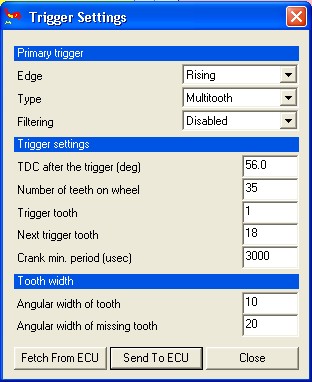

Edge = rising

Type = multitooth

Filtering = Disabled

TDC after the trigger (vr sensor) deg =??

- Can someone help whit TDC after the trigger the number for this regard to my physical set-up

Number of teeth on the wheel = 35

36-1

Trigger tooth = 1

Number one tooth after the missing one

Next Trigger tooth = 18

Crank min period usec = 3000 (assuming a 4cyl that is 6000usec for a whole crank rotation, which is 10000 RPM), but set it lower to be sure.

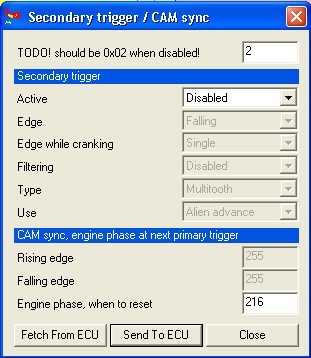

- reset_engphase_after=decimal 216 (which is an arbitrary number for 720 crankdegrees, practical for 36 tooth wheel). The values below are in the same unit:

- Angular width of tooth = 3 (10 degrees)

- Angular width of missing tooth = 6 (20 degrees)

With this non-standard missing-tooth shape, the signal will be bigger aroudn the missing tooth, and R181 (factory-installed on v3.3 ; needs a small and clean tracecut surgery before v3.3) becomes important (min 100k, maybe 180k or higher). See InputTrigger/RunOut

I'd

- measure the signal (record with notebook audio input)

- make a wav-file with slightly even peakier missing-tooth amplitude

- this way check if the setup has the margin for the trigger signal processing.

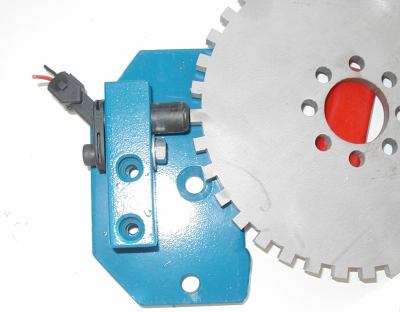

- Thanks for the advice but the standard Ford trigger wheel(crome) will be ok or???

- It should work, but I'd certainly record the signal (with soundcard,scope or other way) so it can be verified. We'll see if it justifies a margin-verification (a next step, playing a wav an see where it starts to make wheel-err).

It's very annoying if the system is near the operation edge, and sometime loses track. In any case, watch wheel-error (mlp01 first line) in case of any hazard.