Stock Opel C20LET engine 4cyl (year ?),

Stock injectors

New intake air and coolant sensor installed

New engine harness

Coil on plug (4 VAG active cop)

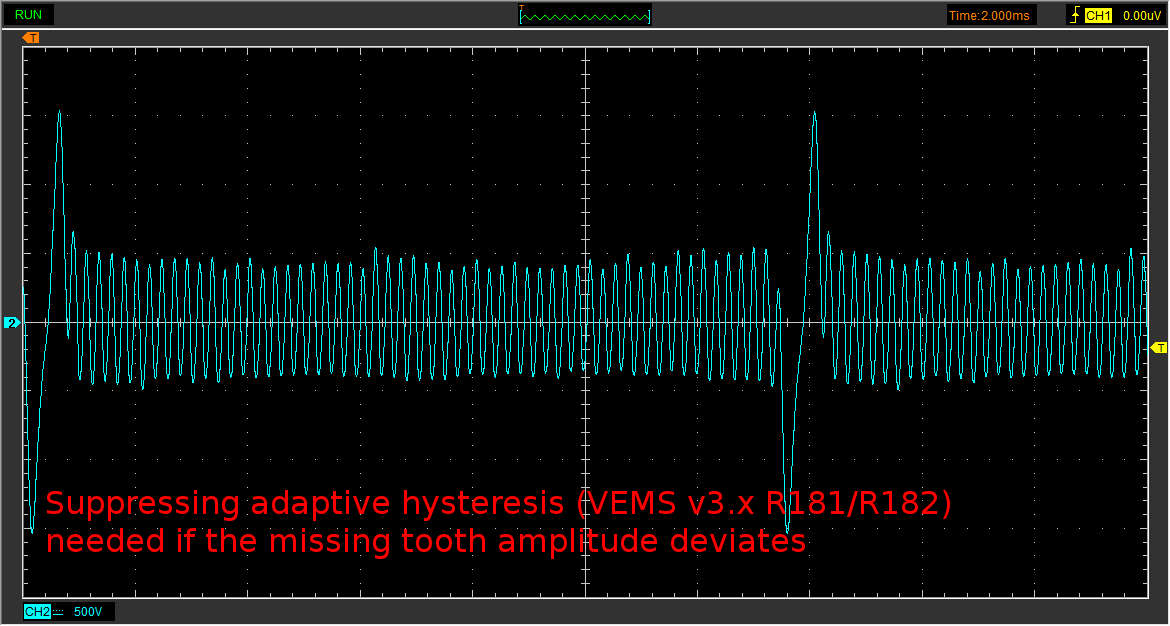

- since the trigger mod for deviating missing tooth wasn't requested in order comment, had to disassemble ECU to modify R181 to greater (>=270k) value

- luckily with active COP-s there is barely any heat on TO220, so the ECU can be carefully tested first without clamping/assembling

Trigger

- Stock primary(VR 60-2)(resistance ~500ohm)

- 90mV with 27k pullup

- secondary(1window HALL) non adjustable triggers.

Should be easy setup (make sure grounds are connected properly)

- order ECU with VR, HALL

- make some DC measurements (eg. VR DC bias voltage)

- connect VR trigger with good polarity

- capture triggerlog

- verify VR trigger polarity

- Everytime I had to change the polarity on Opel 2.0 16V engine with VEMS. This is my 4th C20LET VEMS install. Stock pinout: Pin1=GND, Pin2=Signal, Pin3 Shield GND, I used to swap Pin1 and Pin2 and works fine.

- verify VR trigger polarity

- setup 60-2 (4 cyl) with camsync

- done

- easy if sectrig is at sane position (as usual for opel/GM)

- the chosen edge: either rising or falling edge of sectrig should be away from tooth0 (pulse after missing tooth)

- strobe and fine adjust

Do we wonder that removing pullup does NOT help ?

Trigger types from best to worst:

- HALL type (less prone to noise). For any home-made wheel we can only recommend HALL type

- proper VR type, with tooth amplitudes almost same ("Bosch wheel")

- adaptive hysteresis is a GOOD thing: it allows proper sensing even with greater (amplitude) high RPM noise than the full signal at low RPM (cold cranking)

- worst: VR with stupid wheel (or HALL wheel used with VR sensor)

- the amplitude at the missing tooth deviates (greater).

- supported with greater R181 (at primtrig LM1815pin7). Or R182 (at sectrig LM1815pin7). 270k or greater (~180k factory)

High RPM

There are trigger error and missfire on higher RPM.

Common causes:

- ground connection problem

- New harness, good GND connection on the head.

- sensor mounting vibration

- Hard to check now.

- wheel "runout":

- if some tooth amplitude are anomalyously big or small (or varies throughout the cycle because of "excenter")

- can be cured by fixing the mechanical setup, or by cheating: suppressing the adaptive threshold (greater value R181, R182 ?)

- ECU test: feed m582 sound signal (from notebook or small MP3 player) to the VR trigger. The ECU VR input should sense well beyond 10k RPM (even with auditrigger, which is 135 pulse, not just 60-2).

- Done, ECU trigger inputs GOOD up to 11k RPM

- do NOT flood the engine

- note: (with 60-2) 115200 baud triggerlog needed at idle RPM or higher.

- above 6000 RPM, vemslog can be more useful than triggerlog

- if any problem, also use scope

- scopeshots are in my error report.

Although unlikely to be of issue, a simple test (to see that internal 5V1 zener "voltage limiting" is functional):

- disconnect primary trigger sensor, and apply 12V to EC36/27 VR input via 4k7 or 10k resistor (take note of the details, including measured resistance and VBATT)

- measure voltage on EC36/27

- measure voltage drop on the resistor

- VBATT=12,42, drop voltage on resistor = 5,65V, Voltage on EC36/27 input= 6,75V, resistor=10K

- Voltage on EC36/27 with 27K pullup resistor and connected sensor = 90mV, without pullup resistort = 7mV