5cyl 2.5L double VVT engine volvo/ford engine model: ... can you specify?

- Ford Focus ST 2005-2011 HYDA Engine code.

New measures:

Note: R30=27K on every measure, "MVR+" means Motronic VR input, "MVR- means Motronic VR GND, "Vin" means Vems EC36/27.

1. Measure:

MVR+ 1k to Vin. Voltage= 0.09V

MVR- 1k to GND. Voltage 0.04V

Note:some RPM fluctating, There are trigger error around 5krpm, There wasn't check engine light on idle.

https://drive.google.com/open?id=1Q426MQgFbm0FgfLLGj-NcZycgruu1Lt1

2. Measure:

MVR+ 1k to Vin. Voltage= 0.09V

MVR- 500 ohm to GND. Voltage 0.02V

Note: RPM fluctating, There are trigger error around 5krpm, There was check engine light on idle.

https://drive.google.com/open?id=1wveGA_rbgIwj3bZnQ7NIaogzofe_VusG

3.Measure:

MVR+ 1k to Vin and pulled up to 5V with 27k ohm. Voltage= 0.3V

MVR- 500 ohm to GND. Voltage 0.03V

Note: RPM signal bad around idle, high rpm seems good but on 6500-7000rpm got trigger error.

https://drive.google.com/open?id=11zUAMi8DWhclIZuPnAHarDIuU65LqGHd

4.Measure:

MVR+ 1k to Vin and pulled up to 5V with 18k ohm. Voltage= 0.4V

MVR- 500 ohm to GND. Voltage 0.04V

Note: RPM signal bad around idle, high rpm seems good but on 6500-7000rpm got trigger error.

5.Measure:

MVR+ 1k to Vin and pulled up to 5V with 27k ohm. Voltage= 0.31V

MVR- 500 ohm to GND. Voltage 0.06V

Note: bad idle signal, bad high rpm signal,

6.Measure:

MVR+ 1k to Vin and pulled up to 5V with 27k ohm. Voltage= 0.3V

MVR- 100 ohm to GND. Voltage 0.01V

Note: bad everywhere

7.Measure:

MVR+ 1k to Vin and pulled up to 5V with 31.7k ohm. Voltage= 0.27V

MVR- 100 ohm to GND. Voltage 0.02V

Note: bad idle, not so bad high rpm. not realy good.

8.Measure:

MVR+ 1k to Vin and pulled up to 5V with 31.7k ohm. Voltage= 0.28V

MVR- 2k7 ohm to GND. Voltage 0.11V

Note: There are some idle fluctating, good mid RPM signal, RPM signal lost around 6500rpm.

https://drive.google.com/open?id=1Q426MQgFbm0FgfLLGj-NcZycgruu1Lt1

Traditional piggyback (2 ECU-s from the same VR, with this, motronic usually just works)

- VEMS GND ... (1k or) 2k7 ... motronic VR GND

- VEMS EC36/27 VR can usually be shared ... 0 Ohm to motronic VR input

- 1k can be good, just always measure voltages with each tested setup (with DVM, or, also with scope especially if not solved after a few hours).

Motronic "trigger error"

Must be the RPM signal for motronic.

It is connected to the VEMS parallel.

The VEMS now runs without missfire/trigger error. I can change the pullup resistor from none to 13k so it doesn't matter. Now it has 13K pullup resistor,

The voltage on 36/27PIN:

3.2V without sensor, 3.7V With paralell connected to Motronic (indicating some pullup inside motronic)

- 0.12V with sensor

- The VR sensor resistance: 300ohm

- 0.12V / 0.3k = 4mA current through the sensor, 0.3mA coming from VEMS, and most coming from motronic

Originaly the primary trigger VR sensor connected with 2 wires to the ECU.

Pin 1= signal

pin 2= ??GND??

Both pin has +2.5V to Engine GND

Resistance between two pin: 11.76K ohm (that might not be a valid measurement)

I tried to pull up the pin1 to +5V via 3K,

The voltage after pulling up on:

Pin1= 4.88V

Pin2= 4.6V

Why not measure voltage with 1k pulldown to ground ? (that is the usual measurement of anything that is not 0V but biased by some pullup)

- i did. I measured 0.05V

After this i connected to the VEMS EC36/27 pin with 2k7 resistor (note: assumedly 1k would be better ! Just remove or retune the R30=13k VEMS pullup, perhaps even some weak pulldown would help (or move towards the traditional setup instead).

New measure

Motronic VR GND 1k to GND, Motronic VR + to EC36/27 with 1K, R30=uninstalled

Measure:

Motronic VR+ : 0.04V with sensor, 0.33 With sensor,

Motronic VF GND: 0.03 without sensor, 0.33 with sensor.

There aren't check engine light, seems stabil to 3500-4000rpm but after the rtrigger error still cames.

now the voltage on:

Motronic Pin1= 4.38V

Motronic Pin2 =4.17V

VEMS EC36/26 = 3.98V

If i change the pullup resistor inside the VEMS the Max rpm also change when the motronic get trigger error. R30=13K pullup resistor was the best with 2k7 to motronic.

- I can revving to 7krpm but sometimes i got trigger error on Motronic, so it wasn't perfect. (but is Motronic doing anything other than RPM display ?)

- Need the RPM signal to control the power steering pump, engine coolant fan, alternator, while not get RPM signal the display doesn't show oil pressure, oil temp on their's gauges and need for A/C controll

- Have to find a better solution.

Norbi

CAM HALL/HALL:

Secondary trigger sensor on Exhaust camshaft

Third trigger(exhaust) sensor on the intake camshaft.

VVT solenoids was disconnected when i recorded the triggerlog.

Now i have just LESSSECTRIG error.

Here is the triggerlog. http://www.vems.hu/files/Norbitron/GM/newvrcrank.triggerlog

Triggerlog review

Hello Norby,

I have reviewed your triggerlog, the sectrig pulses are all evenly spaced even with filtering this would not work (with 4 pulses per cam rotation), please make another triggerlog with secondary trigger edge inverted (so change from rising -> falling or falling to rising). Than make another triggerlog 8-10 seconds cranking no ign and inj fuse.

Best regards, Dave

Hello Dave!

Here is the new triggerlog, changed from falling to rising the secondary trigger.

http://www.vems.hu/files/Norbitron/GM/riseandfall.triggerlog

Thanks

Norbi

What secondary trigger settings should i use for this?

There are 22tooth From 0th prtrig tooth to first sectrig pulse, second pulse from 0th tooth at 52nd primtrig tooth.

Other problem

When Motronic trigger input connected parallel to VEMS EC36/27 and switch=ON and engine rpm=0 the ETC noise can cause RPM signal fluctation. If i cranking or the engine is running this isn't cause any problem.

Primary VR

- Later it was changed to a new honeywheel 1gt101dc HALL sensor from WebShop .

- does the HALL sensor really sense the VR wheel ? That could explain the symptoms, swapping in HALL sensor with the VR wheel sounds like the wrong track

- Or, if some custom wheel... what is the wheel like, exactly ?

- 60-2 big diameter wheel on flywheel.

- maybe it has runout, or some asymetry ? (slanted, or sg...?)

- Or, if some custom wheel... what is the wheel like, exactly ?

- does the HALL sensor really sense the VR wheel ? That could explain the symptoms, swapping in HALL sensor with the VR wheel sounds like the wrong track

- a VR sensor in place of the 1gt101dc (put back the original) could reveal when captured with oscilloscope (not just VEMS InputTrigger/TriggerLog).

- anyone could suggest some engine/car models with a mechanically compatible VR sensor, or sg. close ? Seems like this very engine also, what is the original engine model ? The engine is a VOLVO 2.5 5cylinder 20VT Engine in a Ford Focus ST.

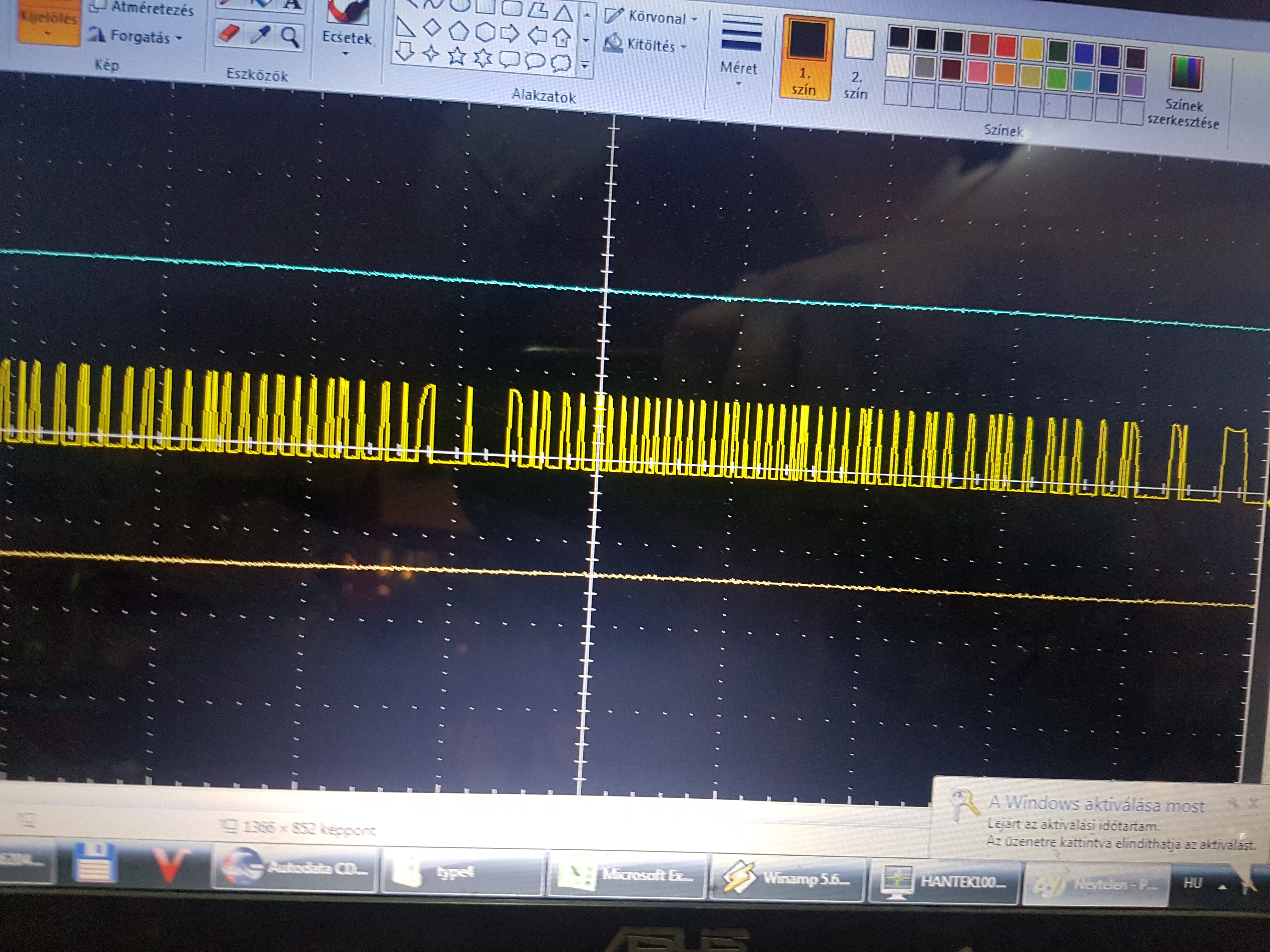

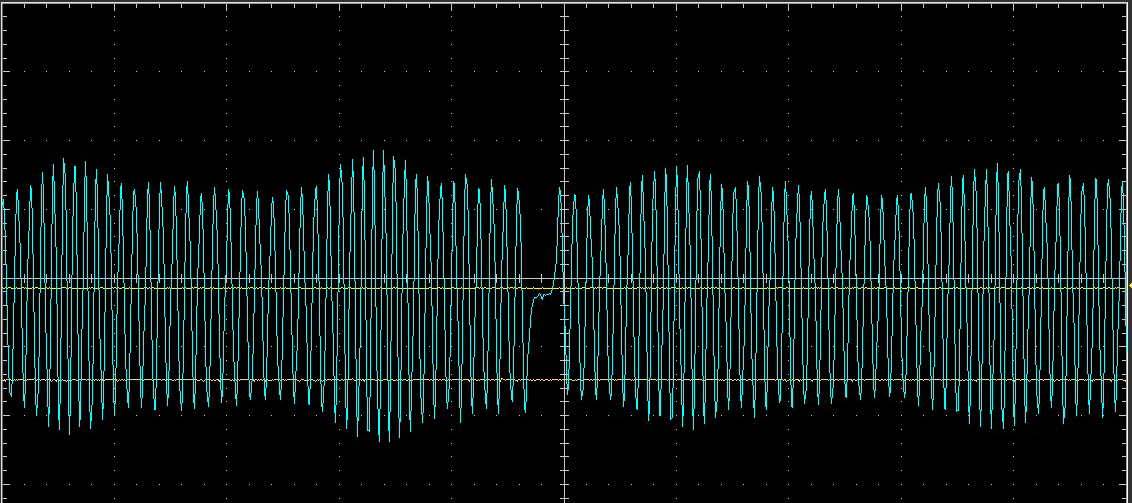

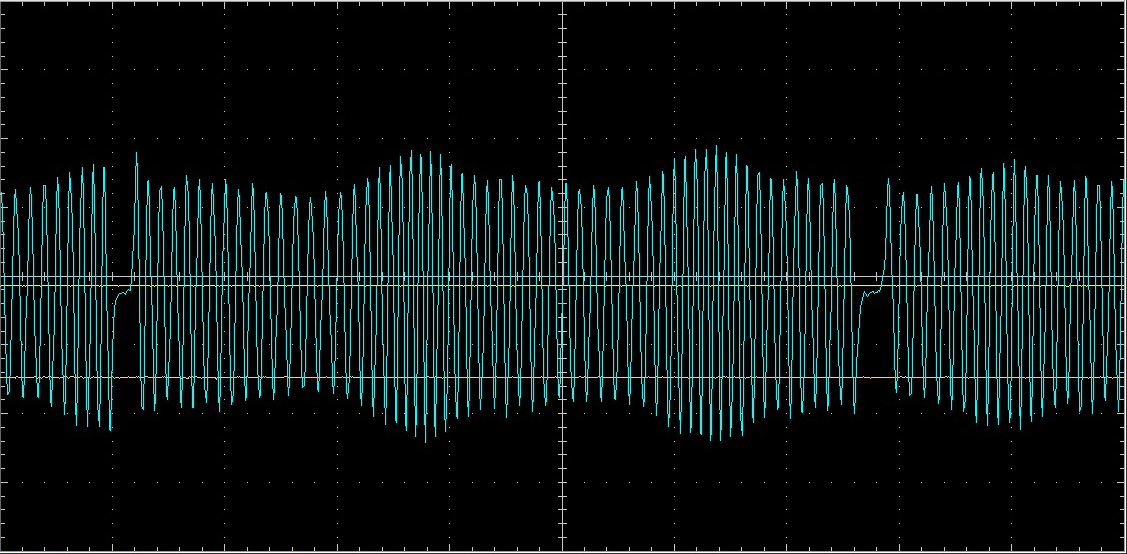

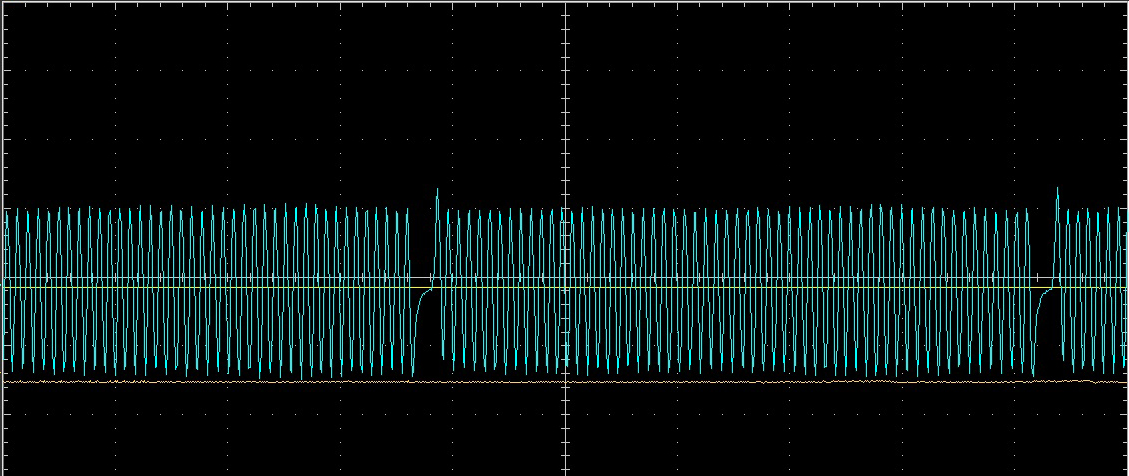

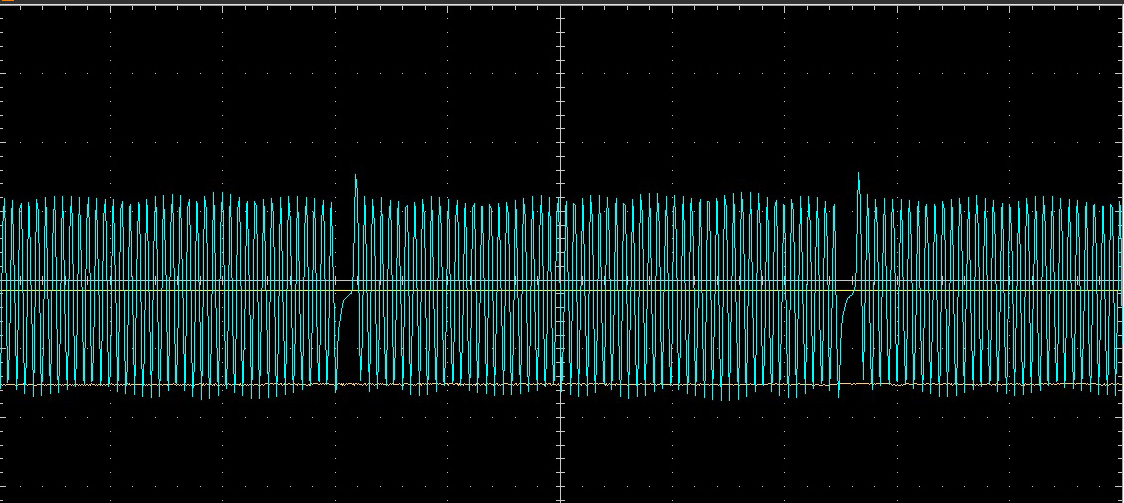

The VR scope captures:

Cranking with VEMS and MOTRONIC

Cranking with VEMS

IDLE with VEMS+MOTRONIC(bit lower idle)

IDLE with VEMS:

CAM HALL/HALL

Fuel pressure sensor

Outside 12V 400kpa MAP

5*coil on plug, drive by +5V logic level.

Drive by wire throttle body

New Intake and IAT sensor, separated from Motronic.

Crank sensor has shielded cable, the shield connected to GND on 1 point.

VEMS and Motronic has a shared Primary trigger signal. VEMS originally had 27k pullup resistor.(pullup resistor uninstalled)

Motronic primary trigger input voltage is 2.46V to GND

Before first start i made two triggerlog, One when motronic connected and one without. Without motronic: seemed good. TDC delay was set up. Started easily. It was running fine, But trigger error flag was on everytime. After this i disconnected the motronic, started easily again but nothing changed... Triggerlogs (captured with 115200 baud ?) seems like a sh..t. when the engine running(also with 1 or 2 ECU, it doesn't matter)

Engine can be revved up to 7krpm without missfire. Maybe there was some small missfire but it was revving up easily.

Some strange symptons:

When crank sensor connected to both ECU, and I'm playing the throttle (drive by wire), the VEMS shows CRANKING flag, Fuel pump on, and sometimes open the injectors and sparking the coils randomly, Sometimes it showed 10-6500RPM on RPM gauge when i moving the Throttle. It seems shield problem.... but i checked many times and it must be good. When motronic ecu disconnected this problem aren't.

I measured the VR sensor resistance: 130ohm...it seems very very low. I tought this is the problem.

- Any VR scopeshots ? Those would be interesting.

- If VR signal does not cross 0mV, a resistor divider toward -8V could help as an experiment:

- eg 4k7 between VR input and -8V (available on LCD pinheader inside the ECU),

- and 1k between VR input and VR signal.

- If VR signal does not cross 0mV, a resistor divider toward -8V could help as an experiment:

I put out the sensor and seemed It has same house like 1GT101DC HALL sensor. I installed this HALL sensor and changed the VEMS(solder the jumpers and R30=2k7 pullup resistor) and the shielded cable pinout for HALL sensor. The cable still shielded.

So HALL sensor sensing the factory VR wheel ? Seems like the bad direction, That is not a good combination, it might not work !

I recorded a triggerlog when cranking, and on idle. It seems also sh..t when the engine is running. Very strange because this is a HALL sensor with shield from sensor to ECU connector...

VEMS Power GNDs and sensor GND points connected like you always recommend. I connected the GND point on the cylinder head at firts time and after tried on battery - but didn't help.

The engine's GND cable are strong, cranking fast and powerfully.

The other sensor signals seems good. There aren't fluctation....Maybe when the engine running the 5V analogs are dropping 0.01V.

I tried to run the engine without ETC controller(without high frequency/high current), hold the valve manually but the triggers also bad.

I checked the HALL sensor signal with oscilloscope and it seems very very bad on idle. I didn't check the VR signal with scope.

And an other perception: I measured +0.02V between every sensor's GND pin and GND(cylinder head or battery - )

I can't reving the engine up from 5500rpm with HALL sensor. When the fuel tank empty... you can see it on the log file.

files:

5V supply change and acceleration enrichment failure when ETC PID works...)

VR IDLE: http://www.vems.hu/files/Norbitron/GM/VRIDLE.triggerlog

VR Cranking disconnected ETC: http://www.vems.hu/files/Norbitron/GM/VRCRANKING.triggerlog

VR CRANKING with connected ETC: http://www.vems.hu/files/Norbitron/GM/VRCRANKETC.triggerlog

HALL stop at 5k5rpm: http://www.vems.hu/files/Norbitron/GM/STOP5K5.vemslog

HALL sensor IDLE: http://www.vems.hu/files/Norbitron/GM/HALLIDLE.triggerlog

HALL sensor cranking: http://www.vems.hu/files/Norbitron/GM/HALLCRANK.triggerlog

Scope of HALL signal.