This page describes a method to build wood-gasifier, or gas producer. It's better than anything we've seen under 1MWe. We also explain our understanding of why it works so well

Related page: MembersPage/MarcellGal/WoodGasifierEngine

We built about 15 downdraft gasifiers and run several experiments. The target of this page is to save you from spending lotsof resources, time and grief while learning the hard way. If you're not familiar with the technology (yet) you can look up keywords (FEMA, De-La-Cotte, Imbert, [monorator], etc...) elsewhere.

It's very hard to grab the concept for first reading. Reread repeatedly, carefully. Also, check out these [Slides made for a lecture explaining the combined draft gasifier]

How NOT to do it ? FEMA tarmaker!!!

We originally started with FEMA. We built several devices, and ran engines with them. FEMA design is probably the worst design (among the ones that produces flammable gas). Besides the fuel moisture and fuel-size sensitivity it produces a LOT of tar.

The FEMA docs clearly states that it's ment for emergency. But even for emergency, the extreme amount of filtering (because of the tar-laden gases out of a FEMA) makes it worse choice than an Imbert. No surprise vedbil.se guys are so black when using FEMA (read their diary).

Why is FEMA so tar-laden? In short, the zones in the FEMA-tarmaker wander up and down, cooling the oxidation zone and creating a HUGE amount of tar (tar is somewhat like mineral oil: good in some places, but not good when sticking the intake valve to its seat).

Imbert: better than FEMA

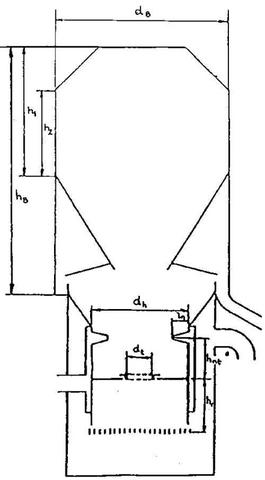

Imbert was the most widely used design in WWII: a reasonable one-stage gasifier design. Usually used for 2-50 kWe but it's very easy to make it bigger. It's quite a challenge to make a good gasifier under 5kWe, because of heat-losses (bigger A/V ratio) and fuel-bridging problems in the small throat.

One embodiment guides air in tangentially, swirling in a toroid at a certain location, keeping temperature up and tar-forming down:

See also [GEK idea] somewhat similar to this.

Big 2-stage gasifiers

Note that for 100-1000 kWe (typical powerplant cost is 800-1000 USD / kW, so the 1000 kWe is ~ 1 million dollar) the trickier 2-stage gasifier (an updraft and a downdraft or crossdraft combined) seems to be a better idea. It can burn fuel with higher moisture content, and bigger or smaller pieces as well. There are some reasonably good 2-stage gasifiers in Gussing, Austria, reaching up to 92% gasification efficiency (that might be a record).

Read about the De-La-Cotte tar-burning gasifier elsewhere.

Internal Tar Burning

The idea is to burn the relatively small amount of incoming air (only 1.6 kg for 1kg wood, giving 2.6kg woodgas) with tar-gases coming from the distillation of wood (not with "clean" char). Also, do this oxidation at a relatively high temp (1200C or higher).

It's impossible to burn all the tar (that would be way too much air, resulting in CO2), but cracking most of them is possible. Most of the cranking happens in the oxidation chamber. Do not expect to crack a lot of tars in the reduction area.

This tar-burning idea is not ours. Besides the De-La-Cotte gasifier that has separate tar-burning chamber, some designs maintain an airflow that helps react the O2 of incoming air with tarry gases.

While we had surprisingly good results without an ejector design, it is almost certain that ejectors (similar to what they used to help firebox draughting in steam-locomotives) can improve the design.

A good example for small gasifier - marching towards the wholy grail ?

The holy grail of gasifiers

- can burn bigger chunks of wood (so chipping not needed)

- eg. 8"-12" long, 1-5" diameter

- can burn relatively moist biomass (not only wood of course - even waste)

- can be operated with low flowrate

- Because of the hopper it will never be really small.

We do not claim to reach all these simultaneously. But it seems that the first 2 targets can be achieved down to at least 2.4 kg/hour wood consumption.

Note that the gasifier was designed for 30-40kg/hour biomass, and mostly for a demo unit (we left improvements for later revision). It is not even completed: heat-recuperation is minimalistic (an external heat-recuperator is planned). And insulation is not particularly good.

We actually did not expect that it operates at 1/13 of the designed peak load (with less tar than a FEMA near design load), so we were a bit surprised.

- A relatively big rectangular hopper, appr 450x650mm

- V at the bottom to allow char to flow down

- d=114mm horizontal auger (with thick shaft) reduction section at the bottom of the V

- many-many nozzles at the circumference at the top of the V

Operation (as far as we understand), apparently similar to the de-La-Cotte gasifier:

- some of the high-temperature gases from oxidation zone flow into the auger

- some of the high-temperature gases from oxidation zone (from the bottom of the V) flow up, distill more fuel and turn down

- flow down at the sides

- mixes with incoming air, oxidizes and travels inwards to the bottom of the V

- the above repeats

Comparison with FEMA:

- in FEMA the tube is small dia. The monorator is the opposite: big diameter, therefore allowing the above gas-currents (up in the middle, down at the sides)

- FEMA has no nozzles. Monorator has nozzles to optimize the point where air comes in

- similarity: both are co-flow. Co-flow is often called downdraft, but in the monorator up-draft currents are also important. And in this implementation the reduction tube is actually horizontal

The auger gasifier produces very good low-tar gas even on inferior fuel like leaves (not suitable for Imbert type).

The 5.2L crysler powerplant with the syncron-generator works like a charm (we tried in island mode). Efficiency can be improved with higher compression and better heat-recuperation.

Problems encountered

- synron-generator not self-excited first

- after long shelf-life it needed 12V applied to some terminals once (when running). After that it self-excited.

- a bigger coin (50 Hungarian Forint, appr d=20mm) stopped the auger (actually this happened in another gasifier with similar auger)

- hole developed in auger, at a bad welding spot (which caused air to leak in)

- easy to fix