http://www.vems.hu/files/KEFOMotoStudent/6-1%2010k.triggerlog

1 cyl motorcycle engine... UPDATE:

http://www.vems.hu/files/KEFOMotoStudent/v3.3_u011448-A-2016.10.09-12.12.18_6-1%20nem%20j%f3.vemscfg

- original advice to use HALL sensor was neglected

- 12-3 was modified to 12-2

- but the glued tooth broke off (multiple times)

- grinder => changed to 6-1 wheel

- had signal problem: the 230 Ohm sensor seeing the original grinded-off-teeth

- other options considered: change to HALL sensor and use "sectrig use a primary". Will not be needed, as:

- cured the ghost pulses of , with 4k7 pullup to +5V => success

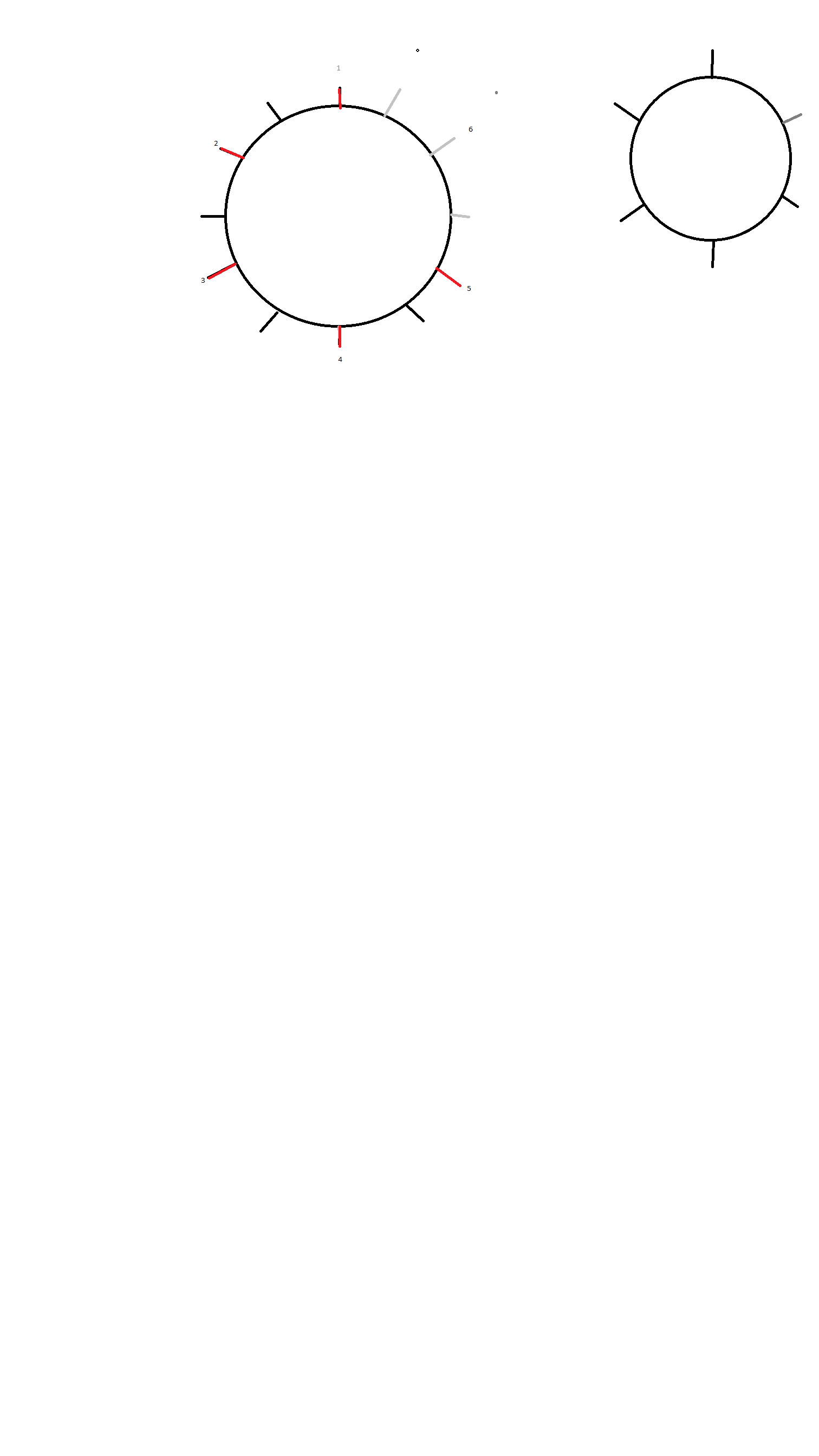

- but proper 6-1 configuration (for ignch6, ignch1, ignch6, ignch1 ; reference teeth 0 3 0 3) is pending, Only ignch6 drives real igncoil

- no strobe, no scope on the racing site, only DVM and notebooks

Pretending 4 cyl engine, but only 1 ignout actually actuated, once per crankrot desired

REFTOOTH (with next trigger tooth=3 : another_trigger_tooth=03

- 0

- 3

- 0

- 3

but the configured ignouts seem bogus:

h[2]=60 50 40 40 40 50 60 70

Ignouts to be configured if you want ignch6 to be actuated once every crankrot:

- 6

- 4

- 6

- 4

We are have a problem, because the tooth which we had glued on, had come down, so we had cut down 4 tooth, to make a 6-1 type flywheel of it. After changing the settings in VT, it is not working. On the triggerlog, it can be seen, that the signal remained as the original 12-3 flywheel. Here's the triggerlog:

http://www.vems.hu/files/KEFOMotoStudent/v3.3_u011448-A-2016.10.09-10.52.32_6-1_triggertooth.vemscfg

pics:

DATE: 09.01

Adjusting the NR of cyl solution worked: RPM shows ~500rpm (reliable, real value). Captured some triggerlogs, but unfortunately, I did not managed to make vemslog, because I had to restart vems, to restart the motorblock, when with the 1-cyl setting, we reached "10000 rpm" (not real RPM) and VEMS ECU automatically applied sparkcut (redshift, as configured).

So here are the triggerlogs:

http://www.vems.hu/files/KEFOMotoStudent/v3.3_u011448-2016-08-30-19.21.18_1_cyl.triggerlog

http://www.vems.hu/files/KEFOMotoStudent/v3.3_u011448-2016-08-30-19.26.45_2cylinder.triggerlog

Additional: we "idled" the engine, first we saw flames in the exhaust, after that we idled at about 2000-2500 RPM, and noticed after 2 minutes, that the exhaust tube is glowing right under the outtake (?), so immediately stopped the engine. ATDC spark ? Perhaps together with excess fuel ? With some other anomaly maybe ? Unintentional "ALS" ?

Did you verify spark position with strobe ? Annotated vemslog with your manual notes about strobed sparkangle (compared to gauges) would be good.

Here's the triggerlog:

Thank you for your support,

Mihály

DATE: 08.30 Vems Support.

I Have reviewed your triggerlogs and vemscfg, intresting; it seems your rpm shows ~5x real rpm.

Try to change the following:

- VT -> Engine Setup -> Number of cylinders:

- change that from 1 to 2 to see if the rpm at least halves.

Please supply a vemslog of cranking and engine running with setting at 1, than another vemslog of cranking and engine running with 2. make sure to power cycle the ecu between setting changes

Best regards, Dave

DATE: 08.29.

So far I have managed to wire up the two temperature sensors (CLT, MAT), these are under calibration. Also wired up the MAP sensor, and tuned it a little bit. And after all that work, we have managed to start the engine (after fuel system egy cooling system setup of course). And a new problem just came up: the CKP sensor (VR type), which shows us an appr. 833 rpm cranking speed, and after start it is 5000-6000(!!)rpm. We do not know it yet, I made some triggerlogs of the problem, I would appreciate, if someone would see them.

Of course the idle speed is not stable, and almost impossible to make it though in this condition. So what do you think of it?

Here are the vemscfg, triggerlog, vemslog (intereseting part is from 405:30) files:

https://drive.google.com/file/d/0B3aVOJowc-6ncU1EeTF3ZFEyaWc

DATE: 08.25.

We had a problem, that the 1.2.31 software, which is working on our VEMS 3.6 is not supporting the N-3 missing tooth, which is the stock layout in our Honda CBR250R motorblock. Managed to solve it in an unique way: after we measured the distance between the tooth, we had created a NEW TOOTH from steel, and glued it on with super strong glue.

PICTURE:

https://drive.google.com/file/d/0B3aVOJowc-6neVVJbXZsQWh0X0k/view?usp=sharing

After testing in VEMS triggerlog by cranking, it works like a charm, I hope, it will in the future too.

So after some cranking, we managed to find out the right TDP with a strobe, which is: FTT=3 and TDP=41,5 deg, and the spark angle compensation is 0 deg.

The next tasks are:

- Sensor Unit(TPS,MAT,MAP) wire up and setup to the correct values

- ECT wire up and setup to the correct values

- WBO2 calibration (it is already wired up)

- fuel system wire up

- injector wireup (caring for FLYBACK)

- fuel managment system wireup (pressure regulator, filter, flyback etc.)

- cooling system wireup

- AAAAND start tuning!

Primary trigger 12-3

It turned out crankshaft position sensor (CKP) is 12-3 type from factory (this is a motorcycle engine). (is it on crankshaft, not camshaft ?)

- N-3 worked in ancient firmwares, but not configurable since 1.1.x

- it's upto anyone to choose any firmware but support normally tests/reproduces setups/puts effort into setups using relatively recent firmwares at the time of install.

- new firmare configured N-2 and cheated (some odd 360/11 deg tooth width) and actually using N-3 could work with some caveat (shown spark advance would be a few percent "off" from real)

EDIT: I have watched this page: MembersPage/AutoVeltiosis , and here the guy solved his 12-3 type with downgrading to 1.0.X the VEMS firmware. I started the firmware update wizard in VT, and found the there is an 1.0.80 firmware.

Downgrade to 1.0.x not recommended.

The 360/11 deg tooth with would need some bench testing. Alternatively a small (heatshrink hidden) arduino adapter could made a 6-2 from the 12-3, by allowing through the following pulses (0 is the tooth after the missing tooth): 0, 2, 4, 6 (filtering out 8, and all odd numbered pulses).

Date: 12 august

So I am going to write down all the information, I collected so far, using my notes.

- Starter motor: R=0,3 Ohm (stock fuse is 30A)

- Crankshaft Position Sensor (CKP):

- 9 tooth, 3 missing

- I measured the resistance in both direction, and it is the same: R=234 Ohm (so it's a VR type???)

- Spark Plug:

- type: NGK IR SIMR 8A9

- Injector:

- 0660 52219 | FBBJF

- Resistance: R=12,4 Ohm -->HIGH-Z flyback needed

- Sensor Unit (on throttle body):

- 5pin

- Pin1: MAP out

- Pin2: TPS out

- Pin3: SG (sensor ground)

- Pin4: VCC (+5V)

- Pin5: IAT out (NTC type)

- https://drive.google.com/open?id=0B3aVOJowc-6ndW5rSUVFR21GOFk

- IACV(idle air control valve):

- 4pin

- stepper motor

- Pin1-Pin4: R=110Ohm

- Pin2-Pin3: R=110Ohm

- https://drive.google.com/open?id=0B3aVOJowc-6nRVExOEtiTTNxZU0

- ECT:

- 3pin

- temperature could be measured between the upper two pins

- VS sensor:

- integrated into the motorblock

- 3-way connector

- Hall-effect type

Parts, we have already ordered from vems shop:

- 1x EC18 connector

- 1x EC36 connector

- 1x VAG COP connector

- 1x LSU4.9 WBO2 sensor with connector

- 3x small switchover relay 12V 20A (Hella)

VEMS pinout in table (hungarian)

https://drive.google.com/open?id=0B3aVOJowc-6nMk5HUXQ4U1ZoSTA

FUSES:

- starter motor: 30A

- fuel pump relay: 20A

- LSU 4.9 (5A)

- between ignition switch and engine stop switch: 10A

- EC36 pin25 (VEMS +12V): 3A

COP pinout:

- 1 - VSS (+12V)

- 2 - Signal GND

- 3 - Ignition pulse from ECU

- 4 - GND

LCD:

- Mechatromotive RCD through AIM protocol

And finally, our options, when ordered VEMS ECU:

Question Nr.1: I heard, that some injector require dashed signal, some require continous signal from ECU. How do I know, which is correct in our case?

Question Nr.2: Which type of diode should be used with the relays?

Preparing VEMS v3.x install;

- VEMS ECU is equipped with 2nd RS232 on flying loom DSUB9 male.

- most useful for 2nd RS232 => AIM data => external CAN interface (for dash, or logger; not for BMW S65 or S65 smart CAN, those use the v3 internal CAN interface)

- or v3 <= 24 extra analog input channels (on top of internal 8+8)

- or special purpose RS485 master or slave (used in powerplants, probably not in this case)

- Please be careful: do NOT accidentally plug LCD into 2nd RS232

08.05.

So now we are on the way, to build up our bike. Some VEMS parts like EC connectors, WBO2 (LSU4.9) sensor and some relays had arrived. have already tested the TPS and IAT sensors with DMM, also tested the IACV, which is a 4pin stepper motor (R=110 Ohm).

Successfully bought a Coil On Plug transformator, which fits well to the engine block.

We are also planning to use a Mechatromotive Racing LCD, which communicates through AIM with VEMS.

Question nr.1: measured the resistance between the 2 CKP sensor outputs, the resistance is the same in both direction, 236 Ohm, so it is a VR type. Please, confirm, if I think well.

Other questions, not very important, only for future improvements:

- does VEMS know, how to handle CAN systems?

- for quickshift/shiftcut, which sensor do you prefer?

So the questions are:

- EGT-input: would you use it in a motocycle?

- Exhaust quantity is much smaller than on other engines. Maybe the 2mm EGT ?

- Injector: which flyback type do you recommend?

- measure injector resistance

- MAP-sensor: we have an external (Keihin) sensor unit, which includes MAP... if MAP sensor signal is between 0-5V => offboard

- Mounting type: what are the other options(no-screws; screws; unspecified) mean in real life?

- choose default or flanged (easiest mounting. The others are for compatibility with old installs)

- VR sensor is the same as inductive sensor (or type of)?

- yes, just "inductive sensor" is a poor name that should never be used (because HALL sensor also measures magnetic induction B, unit=milliTesla). measure resistance in both direction

- SD card is for datalogging.

- alternative option is logging via external tool (PC, notebook, or controller) The logger can be directly connected, or via radio (eg. wifi or BT or special protocol).

- for future improvements: can VEMS handle fast switch

- you mean sudden power supply shutdown ? Careful installation is needed of course. Eg. powerful (max 18V) unidir transient diode should be applied externally. VEMS supply voltage can be +9V or even +7.5V (=> helps power consumption if made with SMPS, and more protection against offensive flyback from inductors like injector(s)).

- maybe you mean "SHIFTCUT" (by "fast switch") ? [Shiftcut] is supported.

- or start electronics?

- yes, if engine is rotating it can be controlled

I would like to use oil temperature and oil pressure sensors:

I found these ones suitable (for pressure):

- http://shop.vems.hu/catalog/differential-pressure-sensor-p-127.html

- https://shop.vems.hu/catalog/pressure-sensor-p-100.html

For temperature, what do you prefer/offer?

I am thinking about using a VW Bora 1.8T ignition transformer (stock number: 715459 0040102043), but I need a 10mm shorter one.

Do you think is it okay to use this on a motobike engine or use some CDI driver? Or what do you recommend?

VEMS supports shiftcut, yes. Input can be shared with launch, or separate (or when launch is not used => of course "separate").

We are building a custom bike, with a Honda CBR250R (2015) engine (1 cyl, 250ccm).

| 1-wire interface | not needed |

| EGT-input (exhaust gas-temp. input) | maybe yes, but not essential |

| ETC BridgeOutput Interface | no need, we have manual gas control (with bowden) |

| Flyback type | still do not have certain information, just the type of the injector (Keihin 0660 52219 FBBJF). Still no DVM to measure resistance ? |

| Hi-side PFET outputs | no |

| Ignition driver | yes, 2+6 (cost-effective and the most suitable for one cylinder) |

| Knock input channels | no |

| LCD connection | yes |

| MAP connection | offboard. We have a Keihin sensor unit (with 5-pin connector) for that, still don't have a datasheet, just serial numbers: 5318A (includes MAP sensor, IAT sensor, TP sensor) |

| Mounting-style | flanged case is good |

| Primary trigger | VR (I have found the stock trigger as inductive, then it is suitable, isn't it?) 12 toothplaces, 3 missing |

| Secondary trigger | no, we don't have camshaft position sensor |

| Special request | now, we have just initial questions, so we have not got any request |

| With SD card | "removable" is removable, to plug in another card in 3 sec, or for quicker download data to PC |