General motors 24X trigger system

Background

This trigger is used on the very popular LS1, LS6 engine and many other V8 engines in this engine family. All these engines are popular to retrofit in cars as it is very light and weigh less then many four cylinder engines. We should try to support it properly.

It is very hard to modify the secondary trigger angle on these engines to get it exactly between the primary trigger pulses.

Problem

It works fine on 48+1 trigger on most cars. The cam sync trigger is however a bit too close to the primary trigger pulses and it sometimes cause a race condition. This seem to have become worse on 1.1.88 compared to the results seen on 1.1.76.

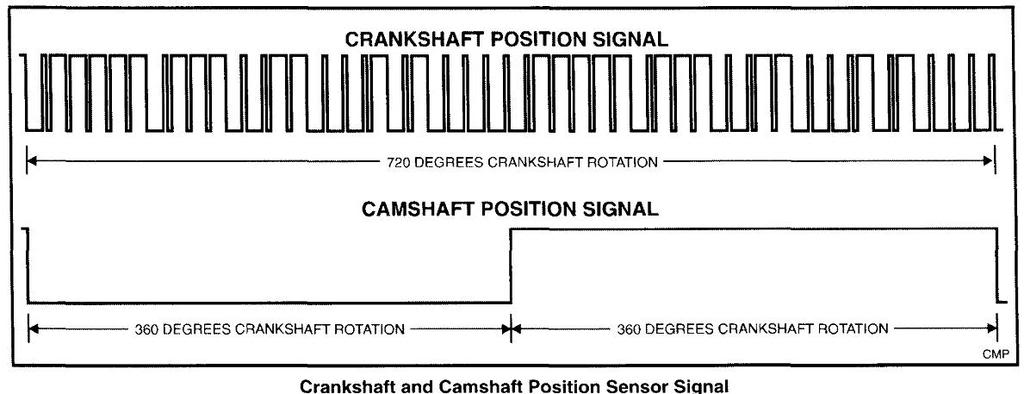

The primary trigger has 24 pulses per revolution where the falling edge of the trigger signal is at 15 deg intervals and the pulse length of the logical '0' is 12 or 3 degrees. As the pulse density is high and the difference is fairly large I think that we can detect this reliably even when cranking. The sync is possible in 90 deg.

Solution

We need to make the engine time the engine from the primary trigger and only use the cam sync sensor for sequential operation. The secondary trigger can possibly be used to simplify starting at low battery voltages.

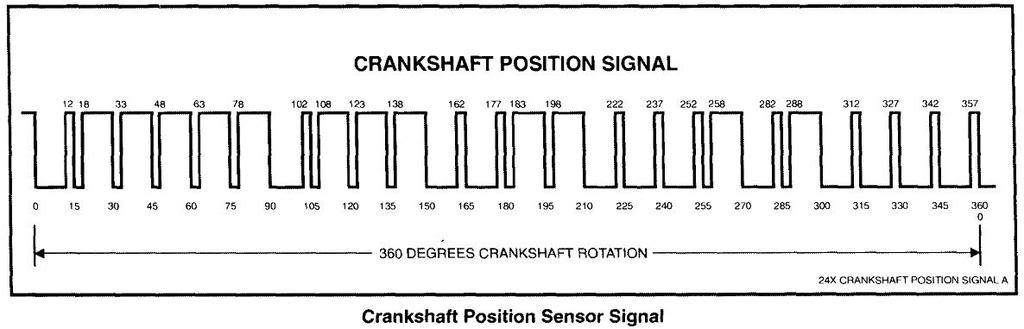

The 24X trigger pattern look like this:

The pattern can be broken down to this:\nÿ1ÿ

If I only specify the length of the logical '0' we get:

0deg to 90deg:

12,3,3,3,3,3

90deg to 180deg:

12,3,3,3,12,12

180deg to 270deg:

3,3,12,12,12,3

270deg to 360deg:

12,3,12,12,12,12

The cam sync has a 360 crank degree duration and will change from 0 to 1 or 1 to 0 around 0 crank degrees. The spec sheet say that it should do it at 0 deg but in reality it occur a few degrees from the previous falling edge of the primary trigger. At least of the engines I have run a trigger log on.

Trigger-detection proposal

- there is some brainstorming about a somewhat error-prone user-configurable campos threshold

- that might be the only solution for lazy-installers on 24+1 (eg. 12 cranktooth) if the campulse is not at the proper factory position (like in Nissan and Toyota), but at some wrong position (which should not actually happen since if it's a homemade setup, it should be 12-1 or 12-2 missing tooth instead of 12 "coiltype" evenly placed pulses, as in a missingtooth setup the camsync position is not sensitive)

For this trigger, it might be possible to make a more specific solution with a few advantages:

- at campulse, the primtrig polarity would be sampled also. There are (apparently) 3 cases:

- camsync comes early, sees high

- camsync comes later (than primtrig), sees low

- camsync comes early, but just when sectrig processing started, pulse goes low (we see low) and primtrig irq gets flagged

I like the above solution. We are ready to try this in the car within hours. We hope use the car on a track day on Thursday, May 5th 2011. I will scope the trigger and I hope to post a few captures of how the primary trigger looks in reality on around rising and falling edge of the secondary trigger.-Jörgen

Another solution could be to turn on primtrig rising-edge irq at some point (around campulse ?). But - if otherwise sufficient - just peeking at the polarity is simpler.

This engine family also use a trigger type called 58X which is what other manufacturers call a 60-2 trigger wheel. For example the LS2 engine use this trigger.