HI!

I'm Fero. I've been using AVR 2.2 since summer 2003, but now AVR 3.1 controls everything in my car. I'm using a turbocharger too:))

My mail: kulinpapa@yahoo.com

My hungarian page: http:\\www.kulinpapa.hu

-My car: 1992 Mazda 323F GT

-Engine: 1839ccm, DOHC, 4 stroke, 4 cylinder, 16 valve, CR: 8.8:1. This engine is called BP at the mazda. The engine is almost the same as in the mazda 323 GTX turbo. There are oil squirters under the pistons to cool them, so it's be perfect for a turbo conversion.

-Turbo: Garrett T25, from an Alfo Romeo. Fully repaired.

-Intercooler: Full Alumimium cooler from a ford pickup, with custom made endtubes. Mounted in the front of the car.

-Exhaust: Custom made exhaust manifold for the turbo, 60mm tubes, and only one muffler on the end of the system.

-Injectors: I built in the 450 cc/min DSM injectors. TRhey're lowZ, approx. 3 Ohm. I drive them sequentially with FETs 00,01,02,03.

-Fuel Pump: I'm using the intank fuelpump of a '92 Mazda RX7. This pump is big enough for big HP cars.

-Ignition: AVR 3.1 controlled dummy ignition with a LADA coil, and stock distributor.Controlled by IGBT 03.

-Variable intake: Contrlolled by AVR, opens the intake tubes at 3300 RPM. Controlled by a FET.

-Idle control: PWM-ing ISC valve. Controlled by a FET.

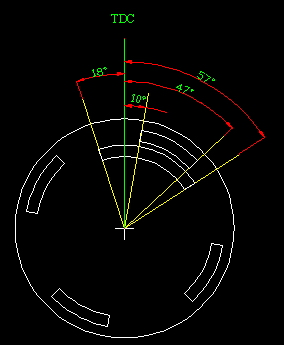

-Input trigger: There is a stock double hall trigger on the exhaust CAM. I use this. I can set primary and secondary trigger from it. Here is a picture about the triggerplate on the CAM:

I measured it with an angle meter. So i hope the numbers are good...

The rising edge of Trigg1 is 47 camdegrees BTDC. It's 47*2=94 degrees on the crank!!! In the config you must write 94*2=188(decimal, in 0.5 crankdegrees)--> BC(hex)

I made a measure with a timing lamp and i modified the trigger delay to A2, according to the timinglight. (let me note that 13 crankdegrees adjustment is significant ! How was it so off first time ?)

- The rising edge of Trigg2 is 57 camdegrees BTDC (114 crankdegrees).

- The falling edge of Trigg2 is 72 camdegrees BTDC (144 crankdegrees) of the next cylinder.

Both edges are good for cam-signal (even with the old code), since they don't fall into the ignition advance window.

Config files:

I'm using the 1.0.23 firmware now.

CAM trigger measuring:

We've made a measuring about the trigger with a scoop. Cell helped me in that triggermeasuring.

Vehicle wiring schematic for v3.1

This is my vehicle wiring schematic. Warning: there could be ERRORS in it!

Always use TimingLight, first on table, than on car. It reveals many types of problems (like missing trigger pulse).

In this case

- trigger was OK, as RPM was correct on LCD

- TimingLight showed that after starting to crank (on table, with stimulus from another genboard - although self trigger could have been used) there was no good ignout signal for several seconds.

- it was obvious that smaller time for higher RPM => suspect it has something to do with the number of pulses (calculation told appr 255..256 trigger pulses)

- we waited more before applying the trigger, and also disabled trigger for some time, to see if it is only the trigger-count, or it has something to do with uptime (time from powerup). It only depended on trigger count.

- think a bit what can cause it :-)

- check engine.igncount initialization in firmware: find that it was misinitialized for the simple (non-missing-tooth) setup. The missing tooth setup that most people use took care of the proper initialization.

checklist

to use for starting problems.

Should be moved elsewhere:

- Does the avr reset during cranking?

- does the AVR see the RPM ? If so, the trigger is there.

- simple 1-Euro TimingLight is the best tool to check the output

Here are some pictures about my board:

[board1] [board2] [board3] [board4]

Rewiring the car for the AVR 3.1

I've been working about 80 hours to build the new AVR 3.1 into my car. I'm almost ready. The car started. I'll made a description about it.B ut until that, here are some pics about the work:

NEWS:

- soon to come: power-curves measured on dyno

- The radiator was blown during the dyno session. It seems there is no big damage (outside the radiator :-), but it was frightening. The cooling might not have been perfect with the dyno. Obviously, there was no pressure alarm installed in the coolant system, but the CLT was not particularly high: the CLT was only 100C while it survived 105C continuously earier on 200km/h highway runs. This is a common problem with this type of Mazda 323, so changing radiator was on the todo list anyway. Now it's prioritized :-)

- 2004.11.18. The first ever breakdown happened with GenBoard/VerThree used in production Actually, it was a wiring problem, not ECM's fault. Probably related to a (failed) attempt to steal the car 2 days earlier when they abused the wiring heavily. Fortunately, the LCD showed that MAP signal is low, so the problem could be located relatively fast: a soldered wire in a DB9 used in the harness for MAP connection broke. Prefer crimped wires (yes: there are DB connectors that can be crimped) to soldered ones. Since there was no notebook in the car, it would have been impossible to fix without towing were the LCD not installed. The connection was temporarily fixed with a duct-tape, than soldered at home. Btw.: there is very good chance the car were stolen had it the factory ECM.

- There was a leak (sealing problem; don't use Al seal before turbo, no matter how thin it is :-) before the turbo, which prevented MAP>150 kPa, but fixed by now.

- The turbocharger is built up into the car!:))) First used with appr. 0.4 bar boost only. The car is extra strong, altough the boost is low. It's crazy fast! Scarry:)) Clutch had to be changed, because it could not hold the power (and slipped).

I had to remove the turbo and wiring pictures. All of them could be seen on my private webpage soon. But the links of the MazdaWiring pictures will be here too. I think it will be ready by the next week.

[ Here] is a link with power measurement the car with g-tech accelerometer. It was only 0.4 Bar boost.

I've written my last school work about VEMS. It's a short(80 page)Megatune for VEMS, and tuning manual in Hungarian language. I think it could be a good starting point to write a good English manual for VEMS. More details will be here later.

New projects:

MembersPage/Fero/MitsubishiEVO