TOYOTA SUPRA V6 biturbo

- 6 cyl , 2.5 L

- 2 turbocharger

- low impedance injectors

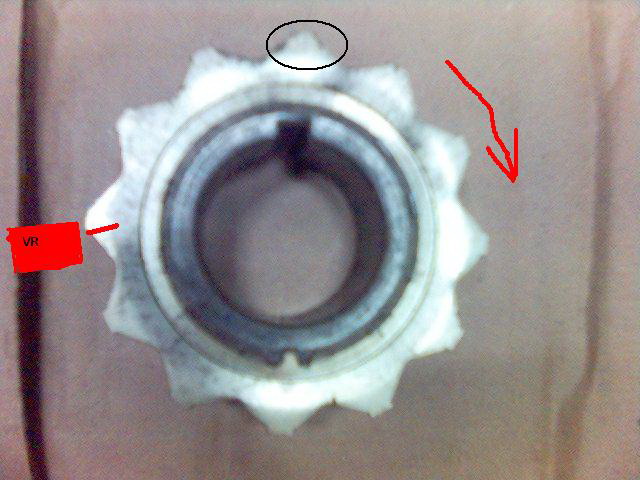

- VR primary trigger

- stock 12 toothed crankwheel (30 crankdeg per tooth)

Dangerous idea - DO NOT remove a teeth

An idea was to remove 1 tooth (black circle) => 12-1 toothwheel.

There is some risk of an abnormally high amplitude VR signal at the missing tooth. Scope (or soundcard) recording of this trigger is definitely a good idea.

Camsync 1 pulse is available (otherwise an M8 screw would do it, used with GT101 HALL sensor, see sensors in WebShop), see InputTrigger/MultiToothNoneMissing and treat it as 24 + 1 setup (as if 24 was on cam; but 12 on crank is better timing precision, of course, because no cambelt sloppniness).

Q: MembersPage/PhatBob what model of Supra is this from? All the Toyotas I've seen have a 12 tooth per crank revolution and one or two cam sync's. I have a fair bit of toyota info so if you could give me the engine number I'll see what I can find

A: 1JZGTE engine. It has two cam sync.

- You should be able to use these triggers without modifying the crank trigger as this is, believe it or not, the same trigger pattern as you find on the Honda, Mazda RX7 and other Toyotas. With this trigger and cam sync you should be able to run semi-sequential and wasted spark very easily.

Config for 1.1.11 firmware

1.1.x firmware

- early 1.1.0 to 1.1.10 only supported missing tooth wheels (with or without camsync) and 135 tooth auditrigger

- since 1.1.11 also supports the simple none_missing toothwheel. This is actually simpler than the missing tooth code. It is configured as "coiltype", but several variable that were "don't care" earlier now are important

- primary_trigger=07 # coil type, filtering, rising edge. Alternatively 06 would be falling edge (could be suitable for HALL, but not for VR)

- secondary_trigger=19 # camsync, rising edge; alternatively 1d is same, but with filtering

- tooth_wheel=18 # decimal 24 tooth (between cam pulses)

- trigger_tooth=00 # or upto 03 ... whatever applies; ign_tdcdelay

- another_trigger_tooth=04 # 24 tooth / 6 cylinders

- tooth_width is allowed to be higher than 64 degrees. The missing tooth width is the upper byte. (there is no missing tooth anyway). Use 0 if the tooth distance is less than 64 degrees.

- tooth_wheel_twidth2=00

- tooth_wheel_twidth1=78 # decimal 120, that is 30 crankdeg per tooth