November 2012

Python program

The install of the ignition is now completed. The ignition map is still the oem Microplex Marelli ecu.

Before 'fine' tuning the map, I asked myself about the data sent by genboard.

VT is a nice tool but for analysis,it may be better to have his own , so I made a Python program

http://www.vems.hu/files/maserati/vemslog.zip

which function plotvlog runs the .csv log file as converted by VT. The arguments are the name of the .csv file and a list of variable names to plot. With ['RPM','MAP',Spark','TP'] one gets

For some reasons variable names from the header of the .csv file are not always the VT ones: TP here is the Throttle Position.

Of course the plot got under Python is interactive plot and allows to zoom etc ...

Noisy RPM VemsLog data

- Noise when idling

The Panvas dataFrame returned by plotvlog can be analysed interactively with Pylab.

Under Ipython with

>plot(dat.index,dat['RPM'])

>plot(dat.index,dat['RPM'],'x')

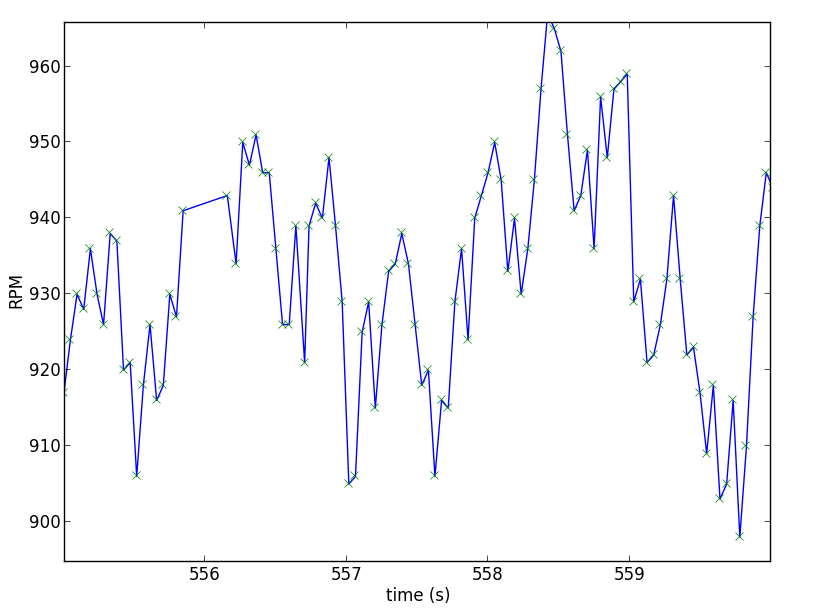

I got a RPM/time plot where I zoomed a 5 s period of idling:

the green crosses 'x' are the RPM values sent by Genboard each 44 ms (or so, this is not the loop period of the internal genboard processing)

On this graph, one sees a large oscillations of the speed due to the idling valve around 925rpm and some big jumps, sometimes as large as 20rpm, at 2 successive 'x' (40ms)

At this idle speed, 40ms is about 220°. As the fire events for this odd engine are 90°,150°,90°,150°, 2 fires can occur during 40ms and this may explain the large increase or decrease of the speed.

However the question is

- Are these jumps equally due to any noise added by genboard/VT?

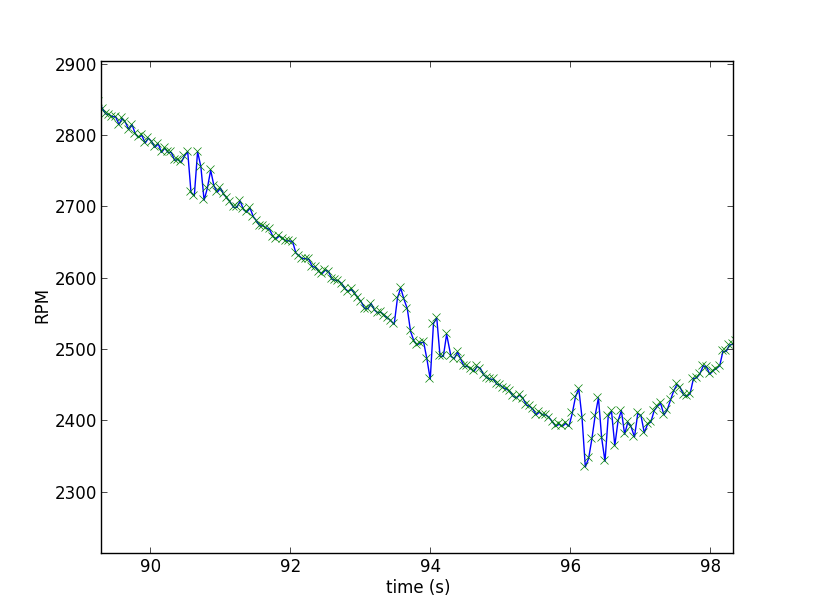

- Noise when running

Some strange transients here occur from time to time

.

.

It looks like the response of a 2nd order filter to some impulsive input.

I have never noticed any misfire when driving, besides they would not make the speed accelerate at the begining. Moreover the pic to pic may be as large as 100rpm. - Nothing on the MAP graph

I do not have any explanation yet.

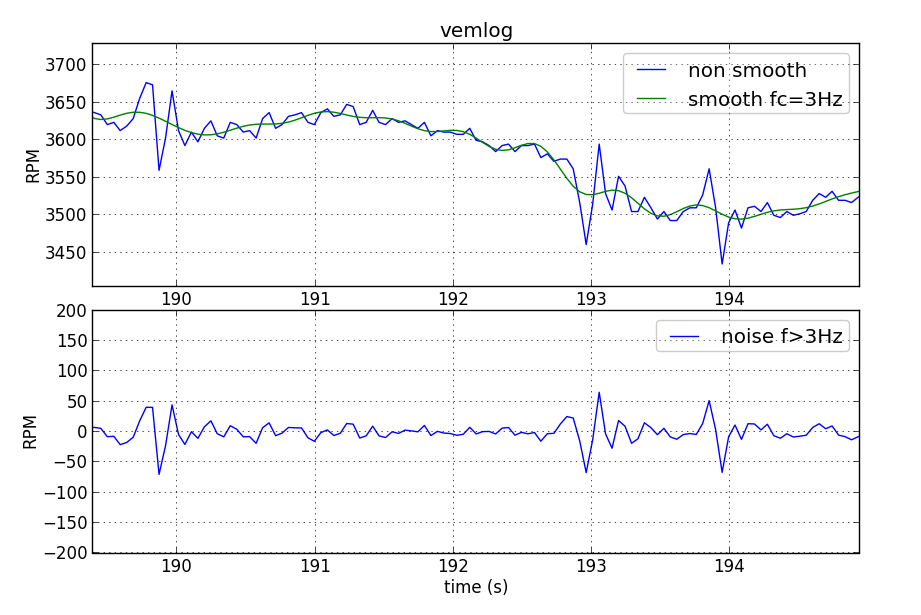

Meanwhile I keep hacking my python program. Now it allows to better show details of these transients:

What about TriggerLog data ?

If one gives the cylinder number to the primary trigger related to it, written in bold when the cylinder has to fire, s being the secondary trigger, we have

s63s 42 51 63 42 51 s63s...

Small gaps are 30°, large ones are 90°. the fw computes the revolution speed after each short gaps (or large ones?). This speed is send to VT at a cte freq, this gives some artificial variation of the speed wich depends of the distance of the last fire at the time the value is sent.

VT allow to make .csv files from a trigger log. Unluckily, for some reasons, the spark events are not recorded

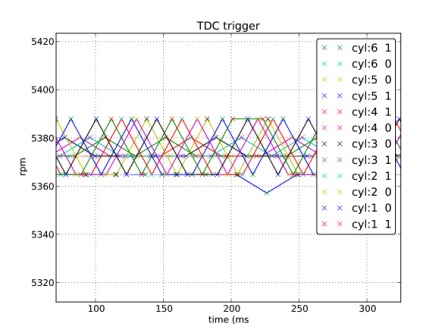

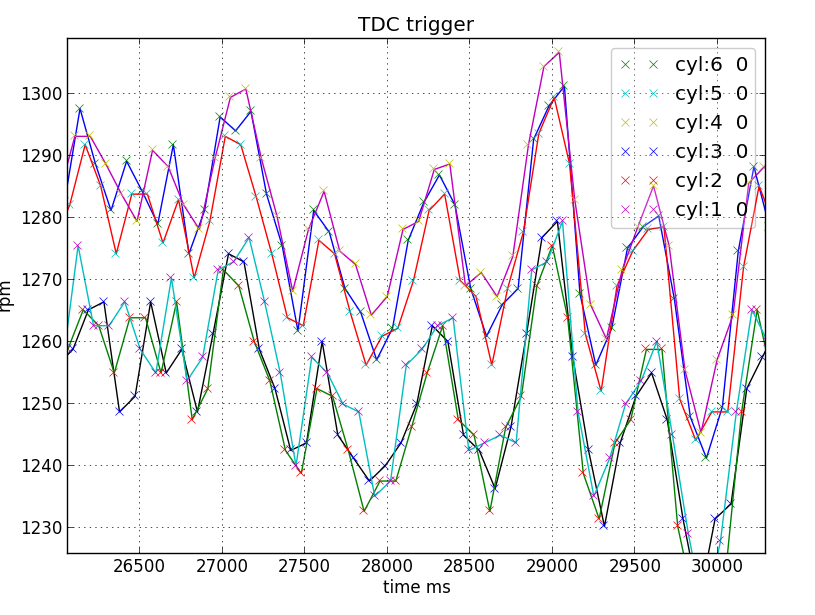

The python programm now allows to plot the revolution speed of each trigger/cylinder which is under spark (bold) or not

Hereafter a zoom of the rpm from a triggerlog recorded at bench (triggers are from the VT trigger tool)

Of course triggerlogs from the running car provide more information. The rpm speed of each cylinder when it is to fire or when it is not, in each of these case, are much less noisy. We see here after per example that the speeds of the cylinders of the left bank(6,5,4)are faster than the speeds for the right bank cylinders(3,2,1). This could be explained by the first group being closer from an ignition than the cylinders of the second group.

I have not yet observed the noise shown hereabove by the vemslog plots.This could prove that the noise is done by the genboard fw.Further logs are necessary

A full analyse of the trigger log whould also give information on the state of the engine and on the improvement obtained by tuning.

April 2013

Acyclism

I have analyzed some triggerlogs from the bench to realize that the time stamps of the log files cannot be used for a close time analysis. Indeed there are, here and there some small erratic time shifts and moreover the sample frequency which is too low gives a noise level too high for a fair interpretation.

I also understood that what I am looking for is to correlate acyclism with torque to get a estimate of the best spark advance point.

Hence I have started a program to record in line this acyclism from the audio input of PC fed by the cam and crank trigs.