Dyno Function requirements:

Sweeps, defined start RPM1(Starting at a static RPM undependent of torque), defined top RPM2 and defined time between RPM1 and RPM2 or defined RPMs/Sec.

Should also be able to start at high RPM1 and end at a low RPM2, running the sweep backwards.

.......

Static RPM undependent of torque.

.......

A constant load (easier to tune acceleration enrichments while allowing the rpms to rise)

Much like a inertia-mode, letting the amount of power decide the acceleration-rate, could be a great future.

.......

Steadystate.

Holding it at a defined RPM for defined timed before moving to next defined RPM (every 250rpm maybe?)

ECU-Hardware requirements:

Inputs:

At least two Hall-sensor inputs for RPM measurement of each hub(maybe four for future 4wd expansion possibilities).

Maybe a inductive clamp-on inductive pickup, when running cars with automatic transmissions.

Two-four loadcell inputs (4ch of mcp3208. 12bit resolution/channel should be enough, that’s 1nm / unit at 8000nm on 2wd)

Wideband O2 input (One or two)

A bunch of type-k inputs.

Some low-temperature inputs(0-100c - IAT and SAE/DIN-correction, maybe for measuring hub-temperature ? )

Some pressure inputs (Maybe 3-4 ? MAP and Exhaustpressure – and weather-correction)

Outputs:

Two-four 0-5v for controlling the breakingpower.

Coolingfan output (Rising fan-speed when the run is about to begin and running it at a lower speed between runs, configurable. Needs external fan-controller.)

Dyno Software requirements (could be a simple visualstudio application):

Plot:

While the run is made the Torque and HP measurements should be ploted onto a view that has configurable X- and Y-axles.

Be able to choose to plot every run on the same screen(like dynojet, very easy to see differences between every run.

Be able to add several curves directly to the sheet, like map, exhaustpressure egt´s and so on.

Dyno plan with v3 and VemsTune

- v3 input: rpm

- Also torque input from loadcell amplifier

- output: pwm 0-100% means 0-5 Volt for the torque controller

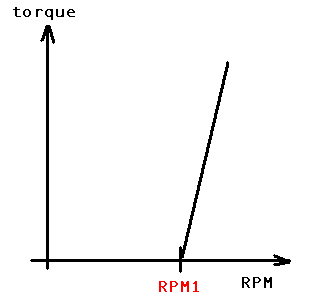

!Simple Torque- rpm curve (for tune):

- below rpm1 threshold output is 0% duty (0V)

- above rpm1 threshold output has very deep slope

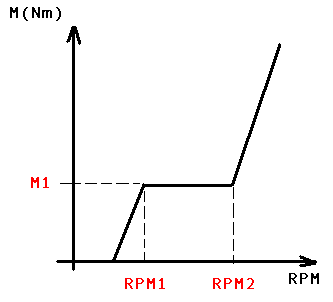

!Advanced Torque- rpm curve (for Tune):

- if the rpm reach rpm1 with M1 torque // output percentage, not measured torque

- in rpm1 and rpm2 hold M1 torque

- above rpm2 threshold output has very deep slope

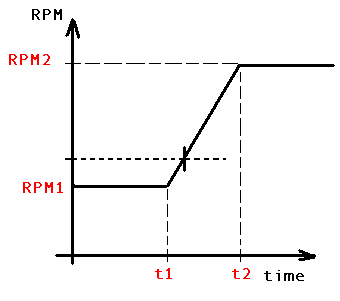

!RPM- time curve (for measure):

- when rpm reach rpm1 then thy to switch form rpm1 to rpm2 with a predefined slope (rpm2-rpm1)/(t2-t1)

- from the measured output(forces torque) the rpm vs torque or rpm vs power can be calculaeted

- All power/torque visualization have to be actual measured torque from loadcell, not controller ouput percent.

Hardware

Measurements made by Arduino MCU using MCP3208 and PID is controlled by V3/RoundV2 (Probably RoundV2), RPM and TargetRPM sent from Arduino.

2 Hall inputs

8 EGT Inputs (0-5v)

2 0-7bar Pressure

2 MAP 7bar

2 Torque inputs (0-5v)

+ Extra configurable 0-5v inputs.

Need High-side output driver from Roundv2! Transformator is controlled via 0-5v or 0-10v (configurable)

Software.

Visual Studio .NET will be powerful enough for this.

Graphic sample: