Evaluating the feasibility of large displacement naturally aspirated 750 RPM double-roller axial powerplant engines. Axial engines are also called "barrell engines".

Naturally aspirated, CR=16.5 for producer-gas (appr 50..55 Nm / liter of displacement equivalent to 4300 Watt / liter on shaft, 4kWe on generator).

Gensets usually achieve 50-110 kWe / ton of weight (the more usual configuration is 1500 RPM engines with traditional crankshaft and connection-rods).

Even worse (and nonsense) > 2000 EUR / liter (NA engines from Russia, India and China sometimes approach 1800 EUR / liter). Generator is only +40 .. 70 EUR / kWe (even with Leroy-Sommer).

An engine with the same-displacement as 6 double-pistons (d=8.5 inch) is about 200-300k EUR. Easy to tell that something in the market is not right. Nice playground for the enterprenous.

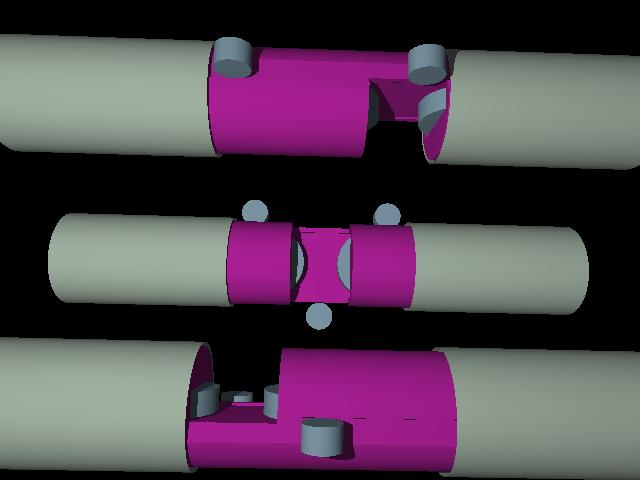

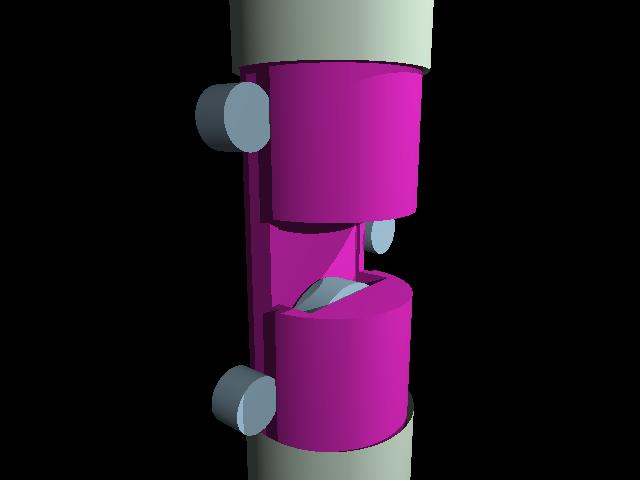

A more reasonable engine would have 6 double-pistons. The engine draft has only 4, and one removed for visibility.

Cylinder liners - displacement

- bore = max 220 mm for now. [Hastings] offers 8.5 inch (=215.9mm) piston ring-sets

- the centrifugal- metalcasting shop specified max 270 mm outer dia for the cyl liner, preferrably max 260 mm if possible. 215.9mm should not be a problem

- for 750 RPM engines 340 mm bore is also reasonable (Caterpillar, Wartsila) but 215.9 mm sounds better for now

- stroke=300..350 mm

- the centrifugal-metalcasting shop specified max 540 mm cylinder liner length

- ~ 12.8 liter / cylinder

2 * 6 cylinders (154 liter total, appr 640 kWe). 2*4 (103 liter) would be another option.

Wet cyl liners or dry liners ?

- originally wet liners were considered

- after discussions with motor repair shops, they recommended dry liner because wet liners have much more sealing issues.

- note: optimally, the cylinders would be cooled by 100-120C termo-oil instead of antifreeze+water: many pellet-plants use 140C termo-oil for drying.

- the cooled oil would be heated by the cylinders (and head) first, than heated by the exhaust (and by the producer-gas) after that

ideas ?

Double roller

Advantages compared to traditional connecting rods:

- connecting rods have 2 bearings, very hard to lubricate

- with double-rollers only 1 problematic bearing remains (per cylinder), which moves to a cooler place and can be much bigger (than the connrod small-end bearing). Very significant !

- and conrods stress the piston rings.

- with the track-roller system most of the piston-ring, piston-groove and cylinder-liner wear is eliminated. Very significant !

- Instead of the crank and connrod big-end bearing 1.5 or 2 (per cylinder) side-roller bearing remains, that is easier to lubricate and damn cheap anyway. (mostly a manufacturing advantage: no big difference in operation costs).

horizontal twin-piston (align their pair) with double roller "swashplate" design.

- NOT wobble-plate! With wobble-plate Marcell doesn't see significant advantage for big engines (compared to the traditional conn-rod design).

Again: appears vertical on this pic, but would be horizontal in actuality

Big rollers are 110..160 kN radial force depending on bore. (bearing for this is appr 150 mm OD, and 3kg)

Side rollers counteract the resulting side forces, and relieve the piston rings from the extreme stresses that wear conn-rod engines in 20000 hours.

Lots of sensors desired to help installation and operation, and detect anomalies early on eg.

- temperature

- movement (stuck, or hardly touching)

- roller force

See

- http://www.eleg.hu/tiki/tiki-index.php?page=Axi%C3%A1lDugatty%C3%BAsMotor

- See 40 sec in [video] in this kinder engine

- note the rollers, and the oil-grooves in the twin-piston

Valves, valve-seat

- traditional

Preferrably compatible with an engine family (Caterpillar, Cummins, whatever...).

intake valves

- 61.6mm intake valve: http://www.summitracing.com/parts/MAN-11220-1/

- [57.1 mm] only 30 USD

Exhaust valve:

Caterpillar valves

- [D9 serial n.18A1]

- Caterpillar 015 intake vave 63.5mm (12.5, 238.5mm)

- Caterpillar 016 exhaust valve 60mm (12.5, 238.5mm)

- why is it so long ?

- Mercedes

- Mercedes 015 59mm intake valve (12, 142.5mm)

- Mercedes 016N 51mm exhaust valve (12, 142.5mm)

The availability of valve guides and seals must be considered also. (and possibly whole individual cyl heads if available).

Camplate

1 camplate at each end of the engine

- with 4 fingers (different radius, of course) on each camplate

- odd cylinders: 1 finger for 2 intake valves + 1 finger for 2 exhaust valves

- even cylinders: 1 finger for 2 intake valves + 1 finger for 2 exhaust valves. Even cylinder fires 360+60 degrees after the neighbor odd cylinder. (for more even running)

- Using rockers (of different length) to actuate the lifters.

Lifters

Mechanical or hydraulic ?

- any suggestions for hydraulic lifters ? Which is the biggest ?

- [Nissan] lifters are quite big, around 40mm diameter

- Peugeot are very small

- VAG diameter is somewhere between

But see [Nissan lifter guts]. The internal diameter that counts (where the oil pressure acts during valve lifting) is much smaller even for the nissan, around 12mm.

Rockers

Rockers are probably the best choice for a camplate (instead of camshaft) engine.

Nice rocker arrangements:

- I like this (US patent 4561391 from 1985): [Mitsubishi-Galant-Eclipse SOHC 4 valve cyl head ]

- Honda introduced the 4-valve XL250 SOHC single cylinder engine in 1972 (13 years before the 1985 patent).

- In 1977 Honda introduced the 3-valve SOHC CB400 twin cylinder models.

- any pictures about these ?

Head

- traditional.

- 4 valves per cylinder + preferrably 2 sparkplugs per cyl

- min 3 valves per cyl in any case.

- Separate head for each cylinder

Oil pump

- electrical oil pump can be switched on before cranking.

- provision for chain-driven mechanical oil pump. One-way valves allow the 2 pumps to be connected in parallel

Coolant pump

- electrical coolant pump

- provision for chain-driven mechanical coolant pump. One-way valves allow the 2 pumps to be connected in parallel

Starter motor

- torque ?

- max RPM ?

- is 50 RPM (more than) enough to start this 12 cyl 750 RPM engine ?

The 3.4MW V20 GE Jenbacher engine (turbo-natural gas 1500 RPM is 21656 Nm, assuming 180 Nm /liter the total displacement can be around 120 liter) is started by 2 x 9 kW electric motor (24V each, ~400A current). It can be started by just 1 of the starters operating. A similar starter would seem suitable for the slightly bigger displacement barrell engine.

A [24V 7.8 kW caterpillar marine starter] 27.6 kg, $195

It is theoretically possible to use the syncronous generator as a starter

- at least with the brush type generator.

- Maybe excitation would be lacking with the brushless type or AC excitation would be needed.

However, this (with the high current relays and added complexity) might be more costly (even with 400V but most likely with a 6-10kV generator) than a dedicated starter motor.

Embedded Steam Engine - doubling as starter

A 2nd axial engine on same shaft, or just 3 steam cylinders (arranged eg as double expansion 1+2 cyl) would allow the engine to self-start on steam or compressed air ("decompressor") like giant ship engines do. During normal operation the steam cylinders would provide added power and efficiency using exhaust heat to produce steam. This would mean +2 cam track on one side (on top of the 2 or 4 required for the ICE cylinders). Steam-oil contamination could be a problem. Also, the steam regulations are very strict. Likely only feasible later, possibly with larger engines.