Because of contradiction between information from the same Subaru manual, start with

Cam info. This helps to decide what is more likely around the crank.

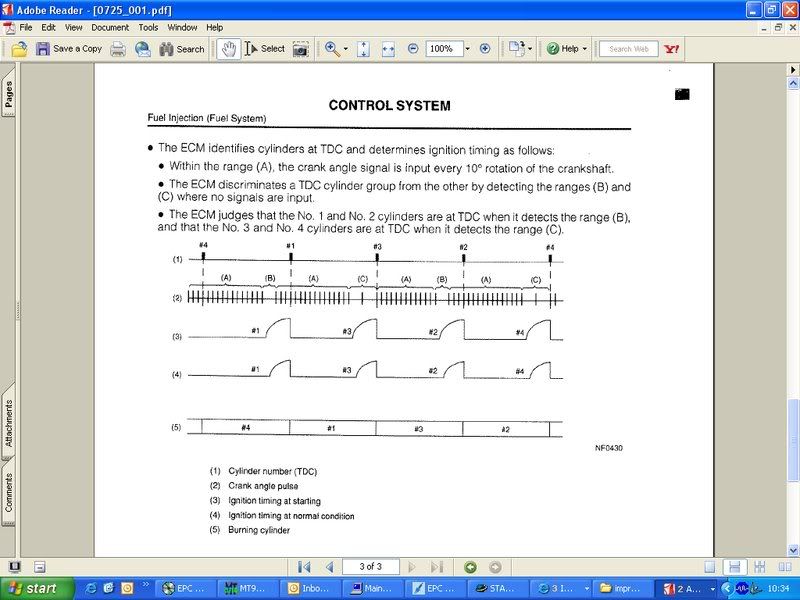

There is a camsync pulse 45 crank degrees before Cyl 1 TDC, then the second comes 135 crank degrees after TDC

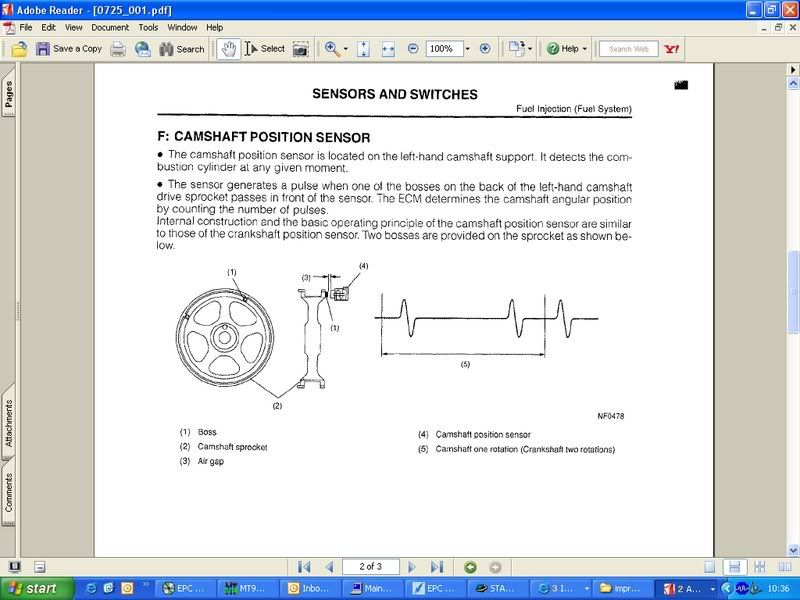

Camsync:

The relative position of the cam (having the camsync pulse coming inside the middle of the long gap) was a reasonable decision.

Now this crank arrangement makes more sense than the contradicting other:

- 36-2-2-2 setup (36 crank teeth, missing 2 teeth BTDC Cyl 1, and 2 teeth twice before BTDC Cyl 3).

- Seen on North American 2.2L SOHC plants (99-01 model using 2 teeth cam wheel) as well as other 2.0L/2.5L Turbo plants (most using 4-1 cam wheel)

The timeline on the pic above and below are contradictory.

Our implementation assumed the above is correct: the double long gap is followed by 13 tooth, not 16.

If anyone scopes the real thing (or just looks at it, or has a photo), please write here: ....

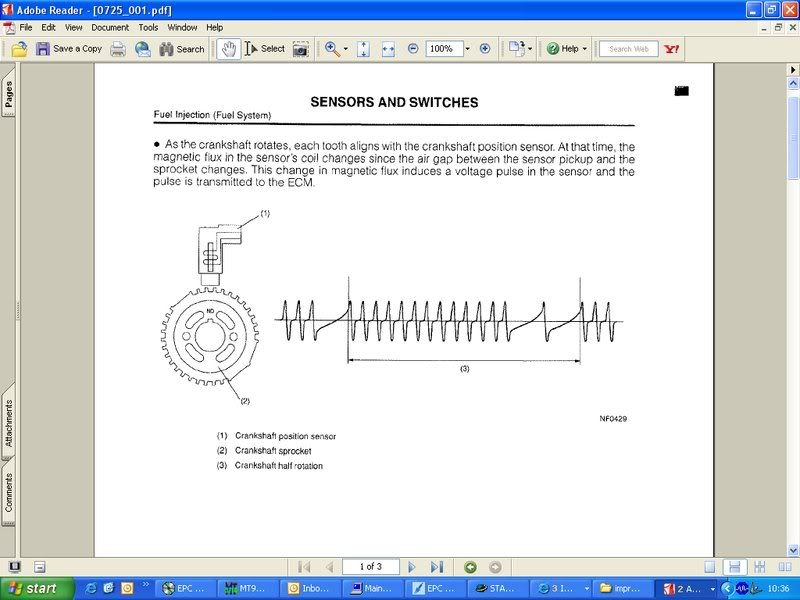

Crank Sensor pattern:

The choice to have the long gap detected at 30 BTDC and 0 TDC is weird.

- for fastest sync during cranking, 40 BTDC and 10 TDC would make most sense.

- for most precise timing during the whole range (and also for programmer's convenience) 90 BTDC and 60 BTDC would make most sense

On both pics with the wheel, it turns anti-clockwise. The engine runs clockwise, but the pic is of the back of the wheel.

We can look at it as 15+3,3+12+3

- TDC is 30 crankdegrees after the single missing gap

- in other words, TDC is the 4th tooth after the single long gap

Subaru 36-2-2-2 implemented with camsync: derived from c012

- |http://www.vems.hu/download/v3/firmware/experimental/ 1.1.78 experimental]

- start from a sane config, than at the bottom of primary trigger dialog click the subaru configlet (so primtrig subaru mode), than change:

- nr of tooth on wheel = 12 (yes, not 30 !)

- tooth width = 30 degree (=3 * normal tooth)

- another_trigger_tooth=6 if 4 cyl

- (3 if 8 cyl, but assuming 4 cyl here)

- reference tooth from top to bottom: 0 18 12 6 ...

- optional: disable camsync.

- But beware: it is ment to work with camsync. Might or might not be possible to set up to operate without camsync. With COPs, use camsync as ign-dualout overloads COP ignition coils easily.

Than burn, and might need to reboot.

Please measure+figure how to set trigger tooth and TDCdelay.

(tooth 0 is after the long gap after the group of 16 normal tooth).

Test pattern

Here is a [wav file] (with CamSync. Inverted to play properly. 670 RPM ?)

- this wav does not match the above spec

- the campulse comes in the first long gap, not the second. But it changes even within the file. The first crank rotation was good. The second crank rotation had the wrong number of teeth after the double gap. A cut and paste error.

- Note the wheels in the above diagrams rotate anti-clockwise since those pictures are looking at the back of them. That may be some of the confusion. So starting at tooth 0 you have 13 pulses, gap, pulse, gap, 16 pulses, gap, and you're back at 0 again.

- Marcell reversed in time, than also had to invert in audacity so the camsync pulse comes in the first long gap (not before it!). Than sectrig-triggerlog showed pulsetrain is reasonable for some testing.

- 2010-06-16 and newer VT also plays 36-2-2-2 in "Tools/Play Trigger" if s362 type is entered manually (even if it's not in the combo, it can be entered)

- now the 2010-06-15 experimental 1.1.76 seems to act properly (36-2-2-2 with camsync). Can be tried on bench or engine.

- the campulse comes in the first long gap, not the second. But it changes even within the file. The first crank rotation was good. The second crank rotation had the wrong number of teeth after the double gap. A cut and paste error.

Of course, it would be wise to scope the real thing.

- Jason can get it to trigger with camsync disabled, and can enable camsync and the rpm becomes closer, but trigg errors. If you stop stim signal it will not register rpm again with camsync enabled.

Here is a [vemscfg file] of the setup described above (trigger settings)

In Jason's engine there is the possibility of using a 4-1 cam signal. It's for the 2004 WRX STi variable cam system (disabled on this engine for now) and those sensors are still there but unused. We should figure out the 2 pulse camsync, but if the 4-1 is easier to handle quickly, I'm ok with that. There is a 4-1 on each cam, but I expect it's sufficient to just read one of the two (just like this 2 pulse cam trigger).