Honda F20 engine

Note: F20C 2005 and up is same trigger wheel as K20X ( Primary trigger VR / others Hall), See InputTrigger/HondaKTwentyTrigger for those

Note: Hi-side PFET-s come handy, see [v3 ECU product options] when VVTI control solenoid needs +12V (grounded to engine block).

All this family is supported by VEMS v3 ECU firmware including camshaft-angle-measurement and control (even on those engines where not continuously variable from the factory).

Configlets for this engine available in VT -> primary trigger -> "4cyl_12+extra_Honda_F20_Camsync"

=== OLD - historical (use the configlets, see above; and anything below should not be needed) ==

Honda F20

From the S2000, this is now a popular engine conversion into older cars and Lotus 7 replicas as it is an RWD engine.

This pic actually shows the late type (2005 and up, see InputTrigger/HondaKTwentyTrigger ).

There are 12 equally spaced teeth 30 degrees apart, with an additional tooth positioned (20,10 deg ??? Or rather 10,20 deg which makes more sense ... And confirmed below and elsewhere).

The engine turns clockwise (apparently this is the only Honda VTEC engine that does) so the trigger pattern is:

..., 30, 30, 10, 20, 30, 30, ...

Now the proper 30, 30, 10,20, 30 ... setup is implemented (along with any similar "extrapulse setup"), also with camsync in 1.1.96 and newer.

DONE: Configlets made for all these since than...

- ...30, 30, 10,20, 30, 30... 12+"extrapulse" crankshaft wheel

- 180, 180, 30,150, 180

- 4+extrapulse like the [Honda K20A] cam

- 120, 120, 40,80, 120, 120, 120

- highly suitable 6+extrapulse trigger on truck camshaft (eg. in producer-gas 1500/1800 constant RPM applications where timing-from crank has marginal advantage - especially that cam is gear-driven (no sloppy belt).

- Faster starting can still be achieved with the help from a good crankwheel trigger (like 36-4 rover k4 MembersPage/YasecElise), but these powerplant engines run all the time, and startup rarely anyway.

- 0(30), 120(90), 240(90), 360(90), 480(90), 600(90) rising-edge-absolute-position(pulsewidth) both-edge sensing HALL-only !

- given that homemade setups are reasonably HALL-type, 6 pulse with one lengthened or shortened pulse also makes sense for custom-machined wheels.

- this needs firmware mod for sure.

- Obviously the 6+extrapulse is better option when made from bolts.

In factory applications the missing tooth wheels are better choices (and actually mostly used: better timing and diagnostics can be achieved without stricter wheel-precision requirement), but for home-made setups the low toothcount (often bolts) are usually appealing.

Bench test results

- Fw 1.1.96 supports as extrapulse trigger

- without camsync use configlet 4cyl_12+extra_Honda_Nocamsync (configure as 12 tooth coil-type + extra pulse trigger enable, ref tooth table 0, 6, 0, 6)

- with camsync use configlet 4cyl_12+extra_Honda_Camsync (configure as 12 tooth coil-type + extra pulse trigger enable + maximum edges between secondary edges = 2, ref tooth table 0, 18, 12, 6)

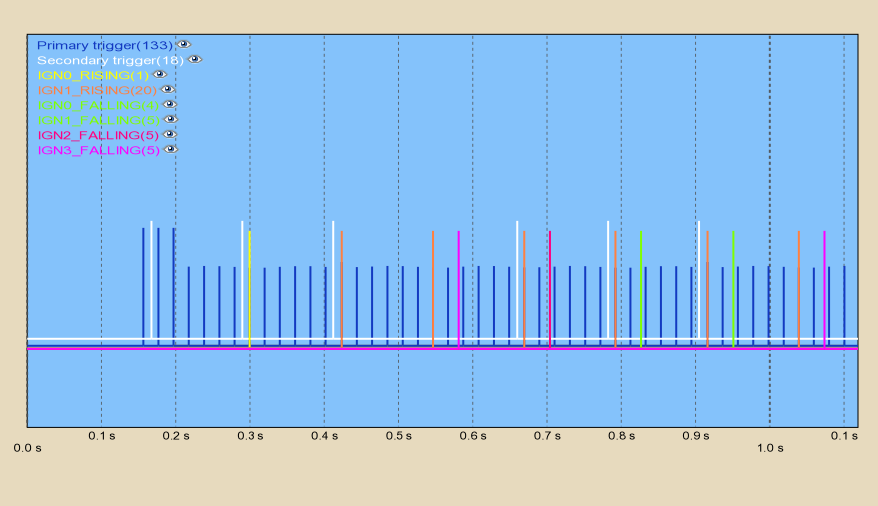

- VemsTune trigger play support ( from VT newer then 2011-07-28 ) as h124 ( h: Honda 12 : 12+1 primary trigger 4: 4+1 secondary trigger)

- Tested [Benchconfig]

'Test on real car

Car is honda type R ep3, 2.0 vtec(also vvti) k20a2 engine.

Vems is connected as pigyback, so stock ecu manage the engine.

Primary trigger:12+1(extra pulse)

Sec: exhaust cam(4+1)

Log and trigger log:

http://www.vems.hu/files/DamirMuha/Honda12Extra/ExhaustCamonCamSynckuglaCivicTypeR-3945.zip

Rpms are good and stable(tested till 8000rpm) only at cranking rpms aren't 100% stable

And for TDC settings are:

TDC after (60deg, not 100% sure, but error is max +-5deg)

first trigger tooth:3

but firing 3. cylinder, not first

Then i connect intake cam to secondary trigger:

log:

http://www.vems.hu/files/DamirMuha/Honda12Extra/IntakeCamOnCamSynckuglaCivicTypeR-3945.zip

It's clear form logs that intake cams move 30deg max with stock ecu.

Connect both cam sensors to vems(sec and third input) for best result (see sectrig and thirdtrig position in log).

- So, my suggestion for honda.

Primary trigger: crank 12+extra pulse

Secondary trigger: Exhaust(4+1) needed for cam sync(working well)

3th trigger: intake(4pulses), needed for campos for intake cam

trigger log of intake cam(for logging is connected to secondary trigger input)

http://www.vems.hu/files/DamirMuha/Honda12Extra/IntakeCamOnCamSynckuglaCivicTypeR-3945.zip

- it's easy to see (from ... what ?) that on idle cam advance is little, but at 2500 WOT is 25-30deg more advanced.

- from this I thought cam position measurement was good.

update 15.8.2011

Car is now running on vems ecu(not mapped).

http://www.vems.hu/files/DamirMuha/Honda12Extra/v3.3_u003945-2011.08.14-22.13.33.vemslog

first ignition coil is connected to vems pin 12, 2nd to 24, 3rd pin 35, 4th to pin 33.

Coils work with logiclevel output 0/5V with stock 510ohm series resistors.

And now tdc is 100% correct.

- first tooth 2

- tdc after trigger 70

- firing 3th cylinder

- bad setting: vvti_measure_tooth is 103 (> 23 ! no such tooth) so cam position always 0deg in log (1.1.96 speed sensor firmware)

- Set in Motorsport/Camshaft angle control/measure at tooth_cnt to 0 or 0..11 (or max 0..23) depending on which tooth you want to measure the cam position. Cam position is measured than.

- according to your triggerlog (that we saved to wav and played back), with measuring at tooth_cnt=10 base position ~23 degree seems OK => also, the following pulse will not interfere even if advanced by 70 crankdegrees (max advance is usually 46..60 deg)

- note the [VT help] for Honda example says "measuring at tooth_cnt = 14" but according to actual triggerlogs that is not recommended: that could result in following tooth too close with your actual sectrigger. Good values are apparently measuring at tooth_cnt = 4,10,16 or 22 but rather 5,11,17 or 23 (+30 deg better clearance, while the following tooth follows > 70 deg later)

- 0 might also work well. It effects the base angle of course.

All three cam sensors are logged good.

http://www.vems.hu/files/DamirMuha/Honda12Extra/v3.3_u003945-2011-08-14-21.57.33.triggerlog

Also VVTI control solenoid needs +12V (grounded to engine block). So added P-FETs mosfet(irf 9540) with gate pulled to 12V with 10k and gate connected to p259 chip. And diode for protection.

Car is mapped on dyno, 242@8500rpm. Vtec and VTI are working.

http://www.vems.hu/files/DamirMuha/Honda12Extra/v3.3_u003945-2011.08.31-20.13.57.vemslog