data upload in progress...

First Honda b16 engine with vems in hungary?

built for drag race

b16a2 engine

forged rods, pistons

darton sleeves

garett gt35 turbo

etc.

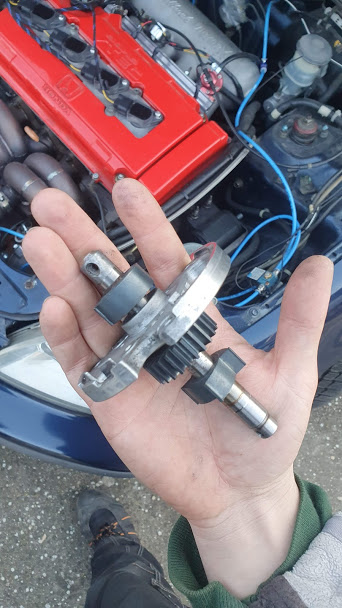

B16 engine has 3 VR trigger in the distributor. 24 - 4 - 1 teeth coil types.

PINOUT

INJ1 BROWN

INJ2 RED

INJ3 BLUE

INJ4 YELLOW

COIL1 yellow

COIL2 blue

COIL3 red

COIL4 brown

CRANK

CAM

TPS RED/BLUE

IAT RED/YELLOW

CLT red/white

FUEL P green/yellow

MIL green/orange

5v OUT yellow/red

FAN nincs

GND 5V yellow/black

VTEC solenoid green/yellow

GROUND black

15+

ckpp blue solid

ckpm white grey dot

tdcp solid green

tdcm red grey dot

cypp yellow

cypm black grey dot

iac blue/black

pcs red

icm1 yellow/green

gnd lg1 brown/black

gnd lg2 brown/black

12fix/vbu white/blue

oem pinout comment:

ACC - A/C relay

ACS - A/C switch

ALTC - Alternator relay, for control purposes, not present on all ECU?s

ALTF - Alternator switch

BKSW- Brake switch, for control purposes, not present on all ECU?s

CKP - Crankshaft position, (P)ulse or (M)ass, gives several pulses (~20?) during each cam shaft rotation

CYP - Cylinder position, (P)ulse or (M)ass, gives one pulse during each cam shaft rotation

DLC - Diagnostic connector, communication signal to the 3 wire connector next to the SCS connector

ECO - Unknown function (is there an ECO light on D15Z3?)

ECT - Engine coolant temperature

EGR - Exhaust gas recirculation

EGRL - Unknown function (probably related to EGR)

FANC - Fan relay, for control purposes, not present on all ECU?s

FLR - Fuel relay, 1 is always present, 2 can be ignored

IACV - Idle air control valve, controls the 2 wire type IACV valve

IAT - Intake air temperature

ICM - Ignition pulses, 1 is always present, 2 can be ignored

IGP - Battery feed, only active when key is turned

INJ - Injector, the number refers to the cylinder used (1 is on the side with the belts)

LG - Ground for battery circuit

MAP - Manifold absolute pressure

MIL - Motor indication light, this one gives the control engine light (CEL) signal

PCS - Control solenoid, this one is for the small black cylindric valve on the back of the IM

PG - Ground for battery circuit

PO2H - Primary oxygen sensor heater, connects with the ground of the car to activate the heater

PO2S - Primary oxygen sensor signal

SCS - Service connector switch, checks if the SCS connector is hot wired (for reading engine error codes)

SG - Ground for 5V circuit, 1 is for the MAP sensor, 2 is for the other sensors

STS - Starter switch

TDC - Top dead centre, (P)ulse or (M)ass, gives four pulses during each cam shaft rotation

TPS - Throttle position signal

VBU - Back up battery feed, always active (unless battery is removed)

VCC - 5V feed, 1 is for the MAP sensor, 2 is for the other sensors

VREF - Unknown function (probably related to wideband oxygen)

VSS - Vehicle speed sensor

VTM - Oil pressure switch, only -but not always- present on VTEC equiped vehicles

VTS - VTEC solenoid, only present on VTEC equiped vehicles

still under construction

testing now..

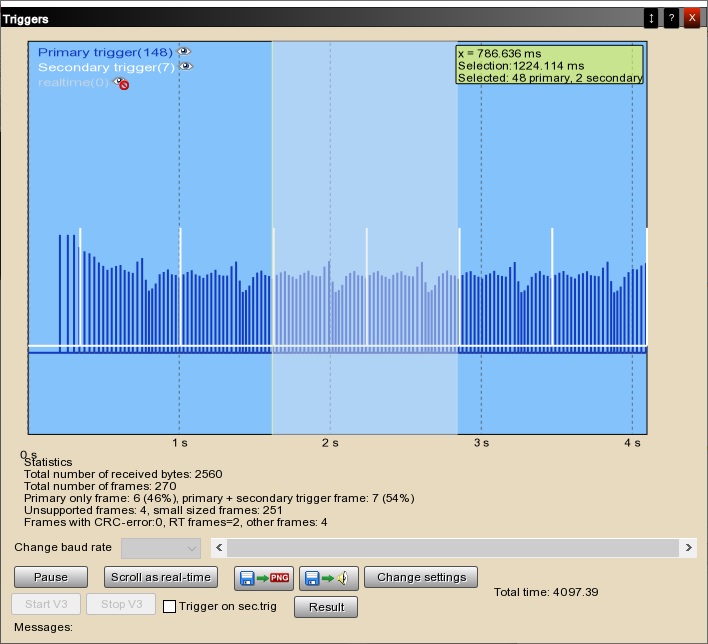

I have problem about trigger signals. I need help.

The iginition system converted to COP.

We have 3 signal on the camshaft/distributor (all of them coil types (VR)).

First wheel has 24 teeth (use this for primary signal)

Second wheel has 4 teeth (not in use)

Third wheel has 1 tooth (use this for secondary signal, cam sync)

In my theory, the ratio of crank and cam is 2:1. So we need to calculate the 24 teeth to 48 teeth for a full engine cycle.

But when I get the 48 teeth by cam, I get two secondary signal too...

http://www.vems.hu/files/tbiro/vti_turbo/v3.3_u014084-2020-03-13-17.09.18.triggerlog

http://www.vems.hu/files/tbiro/vti_turbo/v3.3_u014084-2020.03.18-17.38.29.vemscfg

Tried samples like 4cyl_c024, 4cyl_12+extra_Honda_K20AX_Camsync and others..

I got secondary trigger bad position or less primary trigger errors.

Hello,

I have reviewed your trigger log, this seems to be a normal c24+1 trigger arrangement.

In trigger settings visual enter the following settings:

- Cyl: 4

- Trigger type: Coil type

- Special trigger type: Normal

- TDC after trigger: 60

- # of teeth of full engine cycle: 24

- first trigger tooth: 1

- secondary mode: cam-sync

- press apply to reference tooth table.

- power cycle the ecu after pressing burn, afterwards it should show correct rpm.

Best regards, Dave

Thank you Dave, 24 teeth is only a half engine cycle, am I wrong? (Crank-cam ratio 2:1)

Yes you are wrong, the cam rotates once per cycle, so 24teeth on the cam is 24triggers per cycle. Gunni

Thank you, Dave & Gunni.

The engine runs now, tuning in progress. Tamas

- Question:

The engine is running nicely but there is continuous trigger errors.

I haven't figured out the problem yet

TRIGLOG:

http://www.vems.hu/files/tbiro/vti_turbo/v3.3_u014084-2020-04-15-18.53.16.triggerlog

CONFIG:

http://www.vems.hu/files/tbiro/vti_turbo/v3.3_u014084-2020.04.15-20.36.59.vemscfg