Acceleration Enrichment (Transient Fuel)

Acceleration Enrichment can be derived from two tables.

- RPM Acceleration Enrichment, RPM vs Enrichment PW vs Decay Time.

- TPSaccel Enrichment Scalar, TPSaccel (dv/dt) vs Scalar%

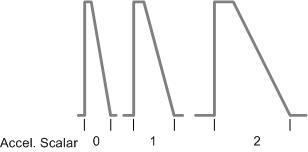

Transient fuel is the output of the RPM Acceleration Enrichment table * TPSaccel Enrichment Scalar.

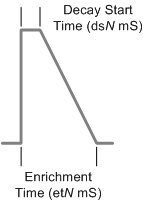

Pulse width enrichment time

RPM Acceleration Enrichment

| RPM | Enrichment PW | Decay Start |

| RPM3 | et3 ms | ds3 ms |

| RPM2 | et2 ms | ds2 ms |

| RPM1 | et1 ms | ds1 ms |

| RPM0 | et0 ms | ds0 ms |

TPSaccel Enrichment Scalar

| TPSaccel | Scaling |

| dv/dt2 | as2 % |

| dv/dt1 | as1 % |

| dv/dt0 | as0 % |

So with With the following entry:

| RPM | Enrichment Time | Decay Start |

| 5500 | 4.4 | 0.8 |

| 4000 | 4.1 | 0.8 |

| TPSaccel | Scaling |

| 50 | 100% |

| 25 | 65% |

Accelleration from 4500rpm with a TPSaccel of 35 would give:

RPM Enrichment of 4.2mS decay start 0.8ms

Scaled Enrichment 4.2mS * 0.79 = 3.318ms decay start 0.8ms * 0.79 = 0.632ms

This is a few things that Dave and I spent some time discussing on the tour. -Jörgen

Req_fuel based

The acc enrichment must be based on req_fuel, we don't want to mess with acc enrichment on each and every system and it's not needed if it's done right.

The current v/s bins and the acc enrich amount values can possibly be fixed. In any case it should be changed from v/s to %/second and the enrichment amount should be set in % of req_fuel. If these tables are uneditable and the values well choosen the acc enrich can be set with the tables mentioned below. If we have 3-5 editable tables affecting the result it's a nightmare to support and debug.

Decay rate

The decay need more attention, first we must decide if we want a fixed decay rate or if we want to make the decay rate faster at higer rpm. Many systems let the accel enrich decay every cycle to make the decay time shorter at higher rpms. I don't know if that is the right way to do it.

Sustained acc enrich

It is also important that the acc enrich is timed from the last occurrance of the acc enrich trigger. With a medium fast throttle application, maybe 1.5s from 0 to 100% throttle the acc enrich must stay on for the entire 1.5s.

Throttle opening vs RPM and angle.

The unlinear response of a throttle butterfly and the fairly linear function between the throttle opening and intake pressure is likely to force us to use a max TPS value that is allowed to trigger an acc enrich. A 3X3 TPSXRPM table with multiplier values will allow us lots of freedom in this regard. (This may however be redundant as the load based acc enrich will give similar results)

- At low rpm even a small throttle opening will let the intake pressure reach almost atmosphere pressure. At higher rpm a larger throttle opening is needed to saturate the plenum.

- A stab from 20-40% throttle at 2k is unlikely to require any acc enrich as the main load variable and the engines fueling requirements are not changed.

- The same stab from 20-40% at 5k is however likely to cause a very large change in intake pressure and fuel requirements.

- If the throttle angle is proportional to the TPS the free flow area will not be very different from 50-100% throttle and little or no acc enrich is needed regardless of rpm in this region. This is also covered with the mentioned 3X3 table.

Acc enrich vs load and rpm

We also need an acc enrichment table with load and rpm. In this table we have a multiplier for the amount of acc enrich needed for this load. Considering the tricks sometimes needed from idle and the sometimes bad vaccum of some engines I think that a 4X4 table is best for this. If it weren't for the sharp increase in vaccum from idle to a few hundred rpm over idle on some engines and some engines high fuel requirement when they are expected to come off a low and lean idle quickly.

Decay rate vs load and RPM

This may or may not be redundant. But a 4X4 table for this is a small cost and it may be made uneditable later if we find that we can get away with it.