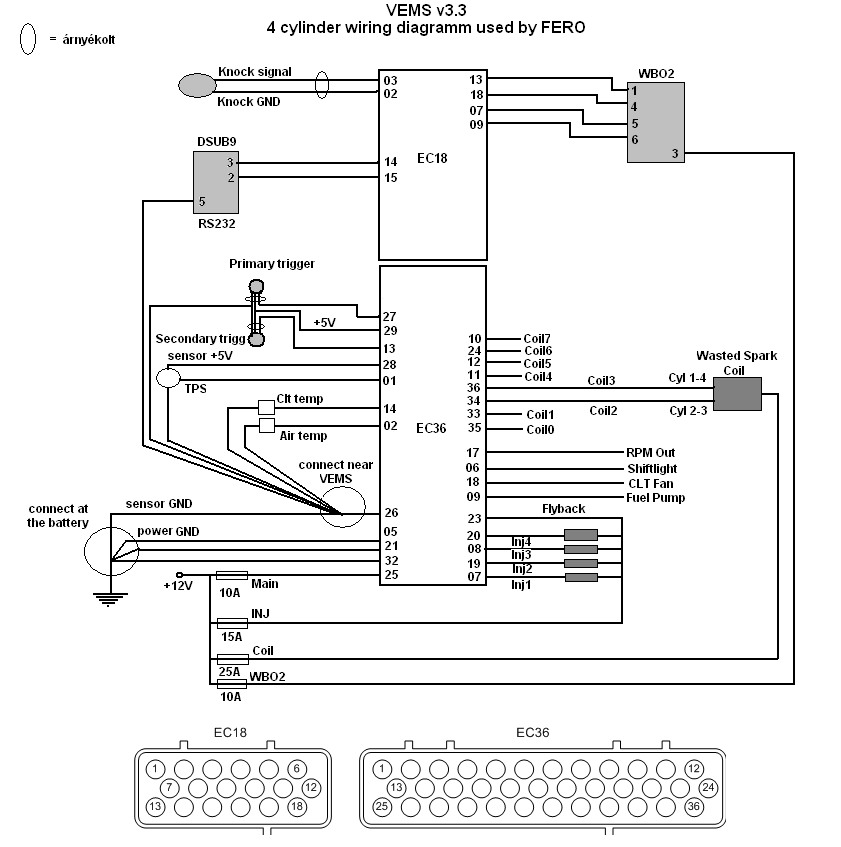

We need to link to a series of different installation wiring diagrams here. Some are already scattered all over wiki. If you have one, please link it here (or link this page from there, so that page shows up in the "reverse-links", when clicking on the pagename in top-right corner).

Harness Discussion

Fully customized harness would be too long latency (also, costly).

It seems possible to make 1 or 2 types of "fits all" harness that is very easy to apply for almost any install.

Write your opinion below ASAP, we're ordering a next batch.

Common characteristics

- relays

- main power relay

- fuel pump

- the original had a small (easy to fix in 5 mins) error here, as the return input of the relay needs +12V (not GND as it was connected). Since the ECU pulls the output to GND

- ...

- fuses

- ECM

- injector

- ignition

- not press receptacles into EC36-wire conn, so they can be applied (to chosen logic-level or power outputs) according to ECU options

- fuel pump

- wideband

- spare channel (fet) 1 e.g. iac pwm (external flyback diode)

- spare channel (fet) 2 e.g. boost (external flyback diode)

- sensors

- iat

- clt

- tps

- triggers

- primary (properly shielded cable usable as either vr or hall)

- secondary (properly shielded cable usable as either vr or hall)

- it might be reasonable to NOT press receptacles into ECxx, so these wires can be used for something else (knock, boost solenoid, whatever) when the secondary trigger is not used (most wasted spark applications).

- proper GND, GND5

- proper flyback

- WBO2 connector

- serial connector close to ecm

- ... ?

Type-F

- F named after "Firewall connector". F0,F1 versions (from different batches have very minor differences). Basic features:

- injectors for 4 cyl

- injector-type AMP connectors for sensors : will be crimped by installer in future versions (since different type connectors exist)

- F0: (original batch, only a very few pieces): ignition was 1+2

- F1: the ignition branch upgraded from 1+2 to 1+10 (max 5 is normally used for ignition. The rest is for extra functions)

- that is one +12V (thicker wire, ~1.5mm2) and 10 wires that can be controlled from ECU. On the ECU side, they can be pressed into any EC36 position (to allow logiclevel or high current drive, or medium current). This allows any kind of customizations, boost, evaporator purge valve, ALS throttle kicker, more ignchannels, you name it

We made a few batches in Hungary, EU at a plan making automotive harnesses. Work quality is very professional. Some recommended aircraft grade wires instead of automotive. For now, they use the same wires as for Audi, VolksWagen and other manufacturers.

Photo of Type-F0:

See http://www.vems.hu/files/Wiring/Harness/ for more pics.

Type-F1 is available in WebShop, as [Loom Connectr/bigharness], best suited for 4 cyl engines.

- see Type-F notes above

- 4 injector channels (8 channel possible)

- 1 + 10 wires at the "ignition" outputs, that is +12V and 10 wires that can be sticked to any Econoseal position, typically 2 wires (for 4 cyl wasted spark) + 8 extra control (BoostControl, staged injectors, NOS, whatever...). But any other assignment is possible, such as:

- 2..4 ignition channels (passive coils)

- 6..8 extra outputs (can be anything), example:

- stepper out

- 2 low power outputs (p259, e.g. tach, shiftlight)

PDF schematics:

- http://www.vems.hu/files/Wiring/BigHarness/pdf/

- a HU=>EN dictionary added now (lame), we'll fix the color names in the .pcb files. Fire a query in webshop if you want the most up2date editable .pcb files (eg. because you want to change color names to English ). See Circad98 below

Type-V available as [v3harness]

[schematics and color dictionary] (the partner used Hungarian colors and some words on the schematic

- no firewall connector. Advantages:

- more appropriate length, the length in the enginebay can be adjusted freely

- lower weight

- lower cost

- the relay part (which is too big to be pulled through the firewall from the engine bay to the cabin, but only has 10 connections to the harness) has a durable 10-pin Econoseal (yes, same receptacles as EC36+EC18) wire-wire connector

- no disadvantages: the harness can come out with the engine easily, just as it could with the firewall connector (only 3 connectors disconnected in the cabin: EC36, EC18, and the EC10 relay connector).

- detachable injector part

- suitable for 4 to 8 cyl

- much room for customizations with MANY extra wires for custom signals:

- 5+4+1+1+1 (ign,inj. sectrig, knock, MAP)

- ground and supply (5V or +12V, fused, even switched by an unassigned custom-controlled relay) available at many places

Problems related to V3 Harness

I used the harness for a 5 cylinder Volvo install the other day, I have one six cylinder harness and one 4 cylinder harness.

- I found that there are two different connectors on the two relay parts that I have. One of them will not mate with the relay connector on the harness. Please check what has gone wrong! -Jörgen

- The connector between the injector harness and the main harness is also wrong, it mates correctly but the pinout is mirrored on one of them. I have the offending connector pair here as I had to shorten the harness for estethic reasons in this case. The second harness I have has the same problem. Please check what has gone wrong. -Jörgen

- Our 2 and 3 pin boots doesn't fit well over the protection used for CLT, IAT, TPS and over the trigger cables. It takes a very long time to fit the boots even with a generous dose of lubricant. -Jörgen

- The trigger ground is routed in the shield, nothing to worry about but worth noting as you can easily loose time when shortening the trigger cables otherwise. BTDT. -Jörgen

Needed Wiring Diagrams (note that all are explained, but schematics aint hurt)

- dummy (dwell controlled by GenBoard) ignition

- directly controlled wasted spark not via EDIS

- EdisIgnition (already explained to details).

Note that injection wiring is independent from ignition, so if you list 4 ignition types and 2 injection, it does not make sense to convolute them (make 2*4 drawing).

We do not want to promote batch injection (it only has disadvantages, many small ones that one can live with, but why?). Otherwise the wiring schematic for batch injection is trivial. Enough to show sequential wiring.

[[Manual: Basics.Install.Mechanic]]

Program to create wiring diagrams

- Corel Draw 11 was used originally: [zipped .cdr file].

- [Circad98] was used by the professional partner

- this is the free win32 version (somewhat limited, eg NO export capability ... but print to pdf via pdf995.com free pdf printer)

[[Manual: Basics.Install.Mechanic]]

Toyota 4A-GE 20v loom (made by Rob, not from webshop):

The schematic an early harness was made from (several changes applied over time, and the number of extra outputs were bumped up by more than +8 by now) :

Back to GenBoard/Manual