We need to add detailed description of sensors and configuration parameters here. Most can be had from GenBoard/InitialConfig page.

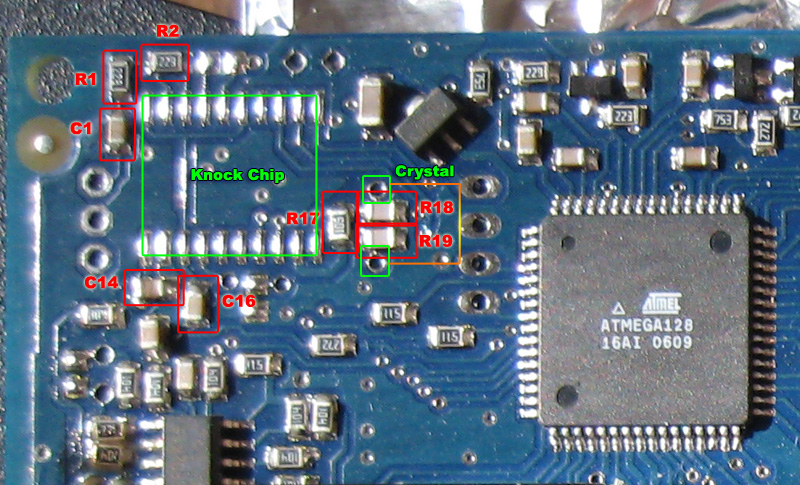

GenBoard/VerThree knockdetection HW

Needed for Knock Sensor input:

- R1, R2 Knock Channel 1 (10..22k) (analog signal amplitude gain can be adjusted with these; but also in the digital domain - in config)

- R3, R4 Knock Channel 2 (same as R1,R2)

- R17 1M

- C1 Knock Channel 1 (100nF)

- C2 Knock Channel 2 (same as C1)

- C14 0.22uF

- C16 100nF

- C18, C19 22pF

- Y2 4MHz XTAL (16MHz might work with matching config)

- U5 TPIC8101DW (not in rescue kit! Optional, see WebShop)

C17 is no longer used. (was: 2.2nF, can now be left off)

V3.2: if you ordered knock-kit (in same order as genboard) than U5=TPIC8101DW and Y2=crystal already soldered onboard (crystal missing on a few boards sent out before 20041030.)

Here you find the top-side components, the second channel uses components on the bottom side too. (thanks to Mr Grogan for pic)

The knock sensor chip installation:

Pin 1 points to the connectors-side. (so pin 1 points to the short side of the board)

The crystal goes next to the chip.

v3.3

The knockchip and 4MHz crystal is installed (if ordered v3.3 with knock-kit), the only thing needed is to connect the sensor input through the 3 pin header (pads) at the northwest corner (looking at the "top") :

- North pad (close to board-edge): knockA signal (channel 0) (usually through EC18pin3)

- Middle pad: knock GND (usually through EC18pin2)

- Southern pad: knockB signal (channel 1) - usually not used

TODO: take pictures of board region around knock chip

If the knock signal is not routed via EC18, it can be routed through a connector or flying loom cable mounted through frontplate or endplate.

Knock sensors

Any sensor (that is used for acoustic knock sensing) should work with GenBoard. The frequency and gain can be configured in software. The frequency depends on engine (mainly bore and cylinder head) while the gain depends on several factors (engine, sensor, screw fastening torque).

It is recommended to verify that sensor can be mounted well. Cling the engine block with a wrench and record the sensor output with your soundcard to measure frequency and verify sensor operation and connection. Especially if the engine bore (the sensor was originally ment for) is very different from yours (say a sensor for a 50mm bore mounted on your engine with 100mm bore)

Knock Sensor Bosch F6020-152717

See also