Intake Air Temperature

Intake air temperature is a critical factor in fuel calculations for speed density control algorithms. The IAT sensor is very prone to heat soaking since it is so close the engine. Heat soak is a situation when the sensor is heated by the temperature of the engine itself to the point that it cannot properly read the temperature of the air entering the engine.

The obvious solution would be to install the IAT sensor as far upstream from the engine as possible; unfortunately the air is heated when going through the intake manifold. The nature of the Speed-density system makes it interesting to know the temperature when the air passes over the throttle blade and when it passes the intake valve. A bunch of factors makes it more important to read the temperature close to the intake valve.

Now we know where we want to know the intake temperature. But as mentioned earlier that will make bad sensors heat soak, a good sensor is more or less insensitive to heat soak. It'll usually only heat soak at very low loads where the air is heated almost to the engine coolant temperature when going through the intake manifold anyway!

Now when we all have acquired good IAT sensors we must consider that we must not get fuel on the sensor! Fuel vaporizing on the sensor will effectively cool it to below the actual intake air temp. Obviously the sensor must sit before all injectors. You must also consider that hot cams often make the engine spit fuel backwards up the intake tract.

Recommendations about IAT sensor placement:

- Throttle body injection. Place sensor before throttle body.

- Port injected with one throttle body and plenum. Place IAT sensor in one of the intake runners.

- Same as above but with hot cam, place sensor in the common plenum.

- Individual throttles. Place the sensor upstream of the throttle blade. (Individual throttles is often used together with a hot cam)

I'll try to find a source for a really good IAT sensor. This is the second most important sensor in a Speed density system.

There is also a configuration parameter that helps prevent this problem while the engine is idling when it is most likely to cause problems. A value of 98 (decimal) will limit the leaning of AFR at idle to 98% at 25C degrees.

- Configuration Parameter: airden_ignore

- Example: airden_ignore=98

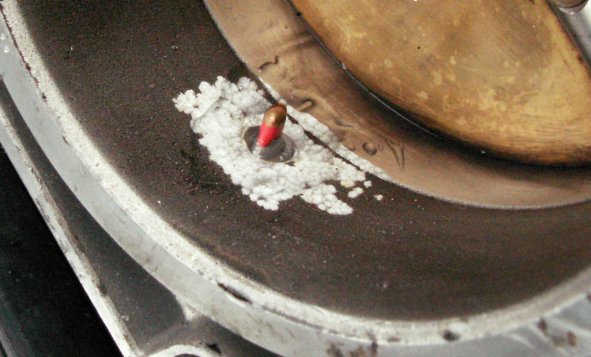

Homemade MAT sensor from the cheap WebShop NTC. Another install:

A "replacable" sensor (only female connector was available, should be male) made from WebShop NTC:

We'll order CLT and MAT sensors.

- the preferred electronic connection is the 2-pin JPT "injector" connector

- I wonder what is the preferred "process connection".

- M10x1

- M12x1.5 seems too big

- M14x1.5 huge

- thread 1/8" - 27 NPT could be another option

- G3/8" also possible (listed first on the manufacturer sheet, and apparently the MOST frequent size used by GM

- Hackish says: here (Canada) we always use the GM sensors because they're so cheap and available, all 1/2 NPT pipe thread. This must be an error, they must be 3/8 NPT, right ?

Any input is appreciated.

See also