Recommended flyback for GenBoard/VerThree: DD flyback

See the new trend, the GenBoard/Manual/PowerFlyback

[Rob's flyback page] - similar content, more pictures

In ancient times, the

- high voltage flyback was the recommendation for highZ injectors, when max 2 injectors (preferrably just 1) used per bank

- and low voltage flyback for lowZ injectors (or when multiple injectors per bank are used)

Since the precise injector opening is configurable (this is a nice feature that not many ECMs have, and no other opensource ECM) usually the low voltage flyback is used also for highZ injectors. In the worst case, there is some adjustment needed (see GenBoard/Manual/Config/InjectorOpening) to smoothen idle if the injector opening parameters were guessed badly originally.

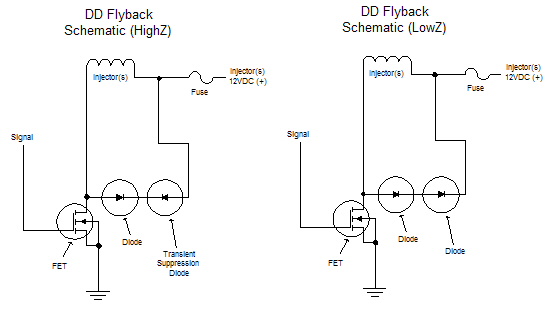

- The left drawing is a high voltage flyback, used only when PWMing is not applied (thus PWM% = 100, recommended for highZ injectors). The flyback voltage drop is

- 0.7V + 6.8V or

- 0.7V + 20V

- The right side drawing is a low voltage flyback for lowZ injectors, where PWMing can be applied. The voltage drop is

- 0.7V + 0.7V for a configuration as on the picture or

- 0.7V + 0V if there is only one diode (or the second is shorted). The 0.7V + 0.7V is preferred by some installers, as the 2nd diode provides protection against the most common (still very rare) failure mode of diodes (when it is shorted)

Notes:

- never have a fuse in the flyback path. The fuse must be outside of the path, as the drawings suggest

- we recommend using separate channels for each injectors

- if one puts in the transient protection diode with anode on the switched side, he'll not get the left side highZ configuration, but the right side low voltage flyback (0.7V + 0.7V) type

- the low voltage type can be used for highZ setup safely, but injection time related parameters are harder to set since injector closing will take longer:

- the low voltage type is definitely suggested if capability of driving highz or lowz injectors is required without HW change.

Recommended low voltage flyback:

Notes:

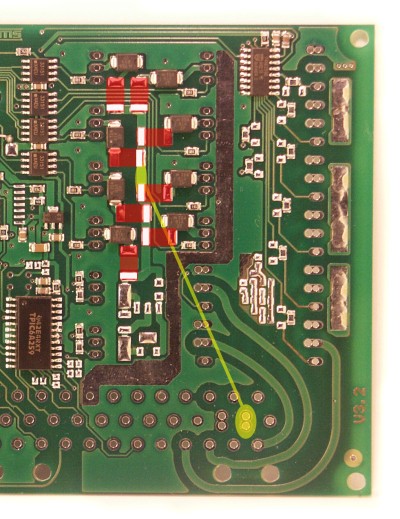

- check the diode direction for the low voltage flyback

- check where the red flyback wire (coming from the connector) is terminated: the best connection is between 4th and 5th diode, so 4 flyback paths are on one side and the current from the other 4 flyback flow from the other side of the onboard flyback trace. The reason for this is that the red 0.61mm2 wire can handle much more current with less heating than the PCB trace

- [high voltage DD flyback with 0.7V + 6.8V and suboptimal placement of the red wire]

- the red wire connects the flyback rail to the EC36 connector, which must be directly connected to the injector common (+) with no fuse in between. This is done regardless if you're using HighZ or LowZ injectors. A fuse is recommended between the supply (main relay) and the injector common (+), but not between the injector common and the onboard flyback trace.

Increasing injector flyback voltage with external diode(s)

If - with a very powerful engine, big injectors - you cannot get a good idle as lean as you like (say it idles OK at lambda=0.8 but not at 1.0), chances are good that the injectors have different injector-opening characteristics (this is possible, even if the flow is equal to great precision when injectors are fully open). We had a case with a set of Siemens injectors. The low voltage flyback does not hide any such differences between injector-opening characteristics.

The easiest way to increase flyback voltage is with a high-current, 2..4V diode: 3..5 BY399 diodes and a 0.1Ohm 5W resistor in series.

- anode connected to EC36pin23

- cathode connected to injector-common.

Use 2 of these (N x diodes and 0.1 Ohm resistor) in parallel.

If you do this, remove D100 ("PJ52 LM" SMB diode among the 16 flyback ES2J diodes) from the board (that provides some protection from forgotten flyback when PWM-ing is not applied; but prevents raising the flyback rail above 18V).

[picture of proposed external mod]

Back to

- GenBoard/Manual/PowerFlyback

- GenBoard/Manual/Flyback

- GenBoard/Manual/Flyback/Calculations

- GenBoard/Manual

- GenBoard/Manual/Flyback/Testing for how to test flyback.

- GenBoard/VerThree/RescueKit to verify what diodes you have

- ES2J and ER2J are identical (only manufacturer is different), 2A continuous (0.7V in forward dir, >600V in reverse dir), 35nsec diodes. Marcell measured with scope, 2 ER2J or 2 ES2J in serial clamp at appr 1.5V (as they should), and very fast, only allows the signal above 1.5V (to appr 2V) for appr 100 nsec. Both ER2J and ES2J behaves the same way, there is no measurable difference, especially for a 64usec period signal. If someone (Emil Larsson?) perceives different behavior, examine carefully, because it's very likely caused by something else (connected differently?), not the ER2J / ES2J.