See the GenBoard/Manual/Flyback page for useful flyback related information.

Forgetting the flyback connection can cause serious damage.

18V unidir transient diode

- eg. SMBJ18A (or SMAJ18A 18-21.1V Ubr 400-600W UNIDIR.)

- SMD diode cathode=EC36/23 flyback and anode=EC36/22 ground on the underside of the v3.x is useful (not essential, but been present on most assembled ECU-s since appr 2013).

- Might provide some last chance protection in case of seriously bad install (flyback forgotten).

- If flyback connection is good, the circuit functions without that diode.

- If the diode is burnt: (only possible with serious wiring problem: after fixing the harness: adding flyback connection to the injector shared +12V)

- preferrably replace SMBJ18

- or use a beefier throughole unidir transient diode: 1.5KE18A 18V (1500W UNIDIR DO-201), inside ECU or in the harness (no problem if there is a diode already)

- or just remove if no spare (damage will be more serious if wiring is not fixed, or flyback connection breaks/disconnects later).

This page is only for historical reasons, for the curious.

For low-impedance injectors the newest tested method with very nice results is MembersPage/DamirMuha/LowZinjectorsFlyback

The flyback design went through a relatively winding road because the widely used motorola MegaSquirt had imprecise fuel calculations and people tried all kinds of workaround hacks to cancel the shortcomings.

The workaround often raised new problems, that had to be solved with more HW complexity.

The road was determined by:

- imprecise fuel calculations =>

- => high voltage FlyBack to make the injector closing less depend on VBatt

- => the PWM-ing (which is common for lowZ injectors) with high voltage (virtual zener-type) FlyBack.

- this dissipates the least amount of heat inside the ECM of all solutions (and also outside the ECM).

- => special controlled FlyBack solutions were developed including microcontroller assisted

- GenBoard/VerTwo actually had the ultimate flyback solution (best for both low-Z and high-Z) but only with 2 injector channels.

- GenBoard/VerThree has 8 injector outputs. Perfect for high-z but needs some widget for for low-z

- for low-Z series resistors were used for years

- but many claim that MembersPage/DamirMuha/LowZinjectorsFlyback gives noticably better results with giant-flow low-z injectors. Since v3 was originally designed with PWM-capability and the ultimate automatic flyback in mind (as an addon), this can actually be plugged to each injector channel (either inside the case or outside). Batch manufacturing is planned in late 2010

Imprecise fuel calculations and actuation (that m.squirt suffered) was not the only problem. It turned out that even with precise fuel calculations and injector pulsewidth actuation there are deviations between injectors of different cylinders (most severe below 1.7 msec pulsewidth) and deviations due to uncompensatable factors (like fuel temperature, viscosity, etc...) so high flyback voltage (30V) when closing is good in any case.

Forgive that the history below is not formatted, the main reason for the junk layeout is that it came from emails.

multichannel LOW-Z injector driving

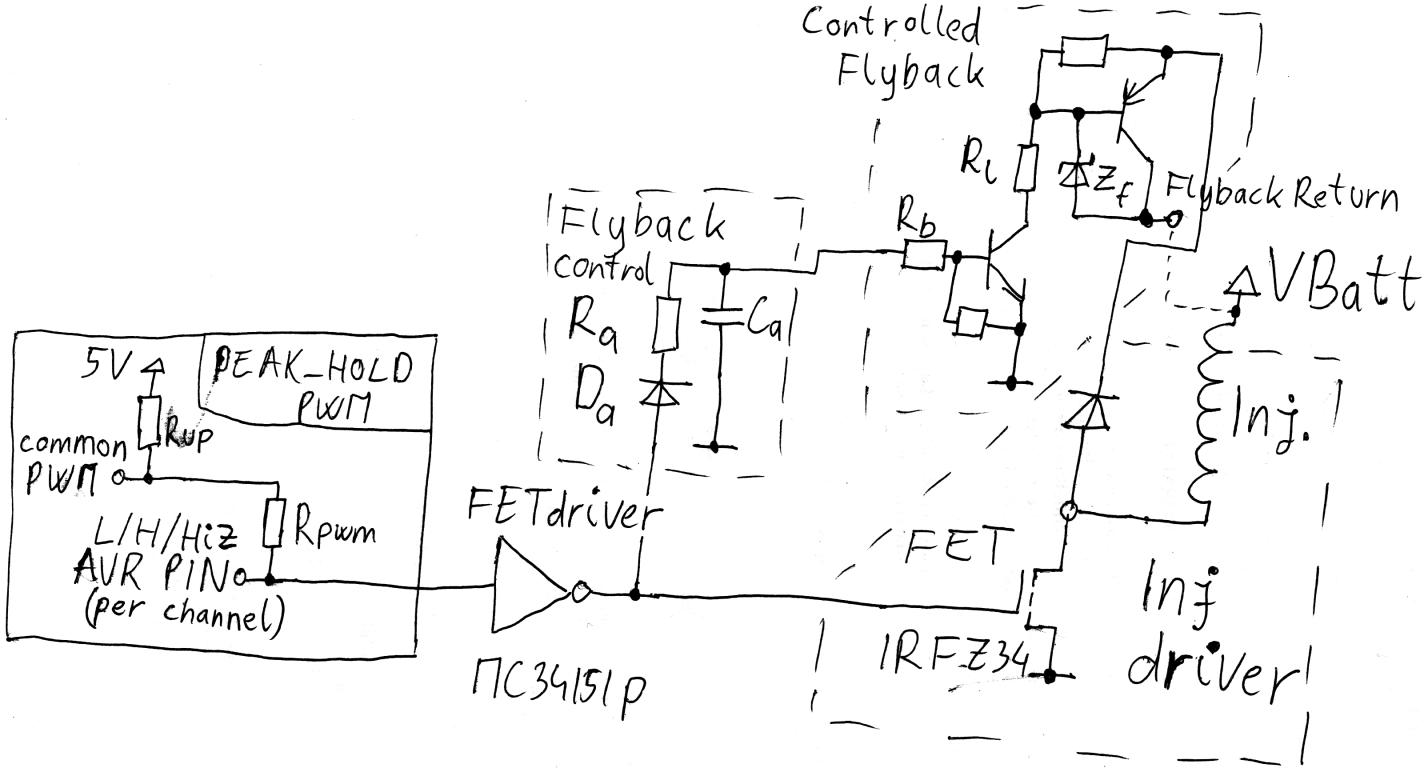

MembersPage/KeithHargrove suggested a very smart, pin-efficient, no gates, no diode method for making PWM-ed signals for multichannel (up to 8) LOW-Z sequential injection:

[  See the Peak_Hold part on the schematic]

See the Peak_Hold part on the schematic]

The first part (uC pin and the FETdriver) is used on GenBoard/VerThree, actually 8 instances of it. The flyback control (delay-circuit) part and the controlled virtual-zener was only built as prototype, since it turned out that it's not needed.

Operation: one pin running PWM all the time feading each of the 8 injectors thru a resistor. And also each injector is connected to an output pin:

- output pin is low = injector on/peak (assuming inverting driver like MC34151p)

- output pin is hi = injector off

- output pin hi-Z = injector PWM

This way we only use one PWM pin. Only a little larger event-overhead than the analog-delayed peak-signal we had earlier (spoken from MembersPage/J├â┬ÂrgenKarlsson and MembersPage/MarcellGal). Personally I like it very much.

- Use 2 PWM-ing outputs with different phase (nice on the voltage-supply rail).

- Connect the PWM-ing outputs to 5V (or GND depending on inversion) via 20kOhm (inactivates injectors when avr-pins are hi-z).

- Connect the PWM-ing output to all the injcontrol outputs via 4..10kOhm.

- Connect the injcontrol outputs to the FETdriver input via 0..1kOhm.

- Connect the FETdriver outputs to FETs and with an asymetric DRC delay to the flyback control (base of NPN that drives the PNP).

This is very space and pin-efficient, especially with R-packs (not individual R-s). The flyback control is derived from the FET-gate signal (a little delayed compared to FET-gate): the DRC delay must be small

- so it activates the flyback before 15% * 64 usec (minimal active time)

- inactivate time must be above 85% * 64 usec so it does not deactivate for the thinnest PWM signal.

Note: we can declare the thinnest PWM signal be 18..20%, not 15%, those who want, can add some series resistors. (this is not more than a board-population / matching config issue anyway).

Note2: those having high-Z injectors probably want to leave out the controlled flyback. There is just no point in it (although it does not hurt either).

Also I am using a sn754410 (not MC34151p) it does not invert but digikey has it.

With many injector banks (like 8), one might consider to forget the controlled flyback and use a common flyback rail and only a diode per injector. A power-efficient (read: not that much heat) switching rail can be constructed:

discussion:

> I like the switching regulator.

> and I do not think it will take up much space

I think 1 might be enough on the board, maybe with a huge

PNP (bigger than TO-220 and on heatsink).

I think it is better to use 2 synced, but phase-offset PWM signals

(64usec period, OCR1B and OCR1C comes to mind) for the

lowZ injectors, so only 4 lowZ

injectors start flybacking at a time, the other 4 at

Marcell

another time. 4*3 A is not a small current in itself..

> can the oscillater stall if it get strange loads or low load.

> I think of any latch-up problems it might have..

I think it should not. A small resistor in series with Z14

might be a good idea (even Z14's internal dU/dI > 0), because

it allows more tolerance for the value of Rf

(note: the NPN changes its h21 with temperature, etc...)

C should be connected to VBatt (not GND, as on the picture),

and be at least 25V, 100uF (rather 220uF, we don't want too high

switching frequency).

> also I think the the box will have more 12V comming out then comming in.

> with all the current from the injectors. We should have the flyback/diodes

> tied to vbatt before any protection diodes

very good point!

I don't like those diodes very much, they don't protect the whole

circuit anyway. I like to short them with 1 Ohm, so I can measure

supply current easily.

I don't apply negative power, I use other ways of releasing the

smoke that was packaged into the chips and wires in the factory :-)

end of unformatted junk (provided only for historical reasons for the future EFI-archeologists)

See FlyBack