Alubos front-plate with window for econoseal connectors

News: having supply-chain problems, we're trying things. It seems the new party will work. [ http://www.american.hu/GenBoardv31/GenBoardv31/TransparentBox/ unresized big pictures about box with transparent frontplate ]. They use a precise, but expensive technology. We will manufacture transparent (for demo purposes) and Al frontplates, but the Al endplate is being moved to another, cheaper technology (with the option of DB connectors).

Assembly warning

It is very important to solder the EconoSealIII connectors with the frontplate applied and verified to the GenBoard/VerThree/CaseAndMounting : otherwise it might be impossible to apply frontplate later (without unsoldering connectors) depending on how the connectors were soldered.

Offsetted frontplates

Thanx to a lousy CNC-er a bunch of frontplates were manufactured with imperfect sizing. The small pegs from the EC36 connector bottom must be removed (or halved, but removing is easier) with a knife and the connector legs bent a bit (0.5 mm not visible as the legs are 20+ mm long). The price is therefore discounted to 2 Euro. They are mixed with a set of good plates, that needs nothing special to make a good match.

The transparent frontplates are not affected at all - those are perfect match and (partly because of the lack of pegs) very easy to work with.

Manufacturing notes

The EC18 (smaller window than the EC36) window is on the left side when looking onto the side without gasket-notches, and the overlap being at the bottom holes. (this is important to verify before manufacturing, because the early revision files had it mirrored!)

looking onto the side without gasket-notches:

looking onto the side with gasket-notches:

The assembled box:

the part press fit together you need to smash them together with a vice or tap them together.

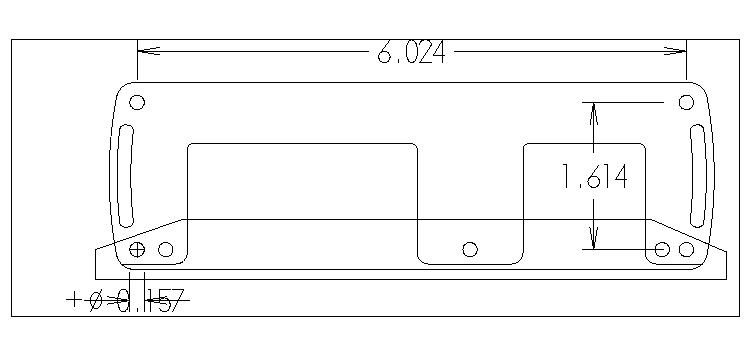

to verify sizes (this picture uses the broken inch unit :-):

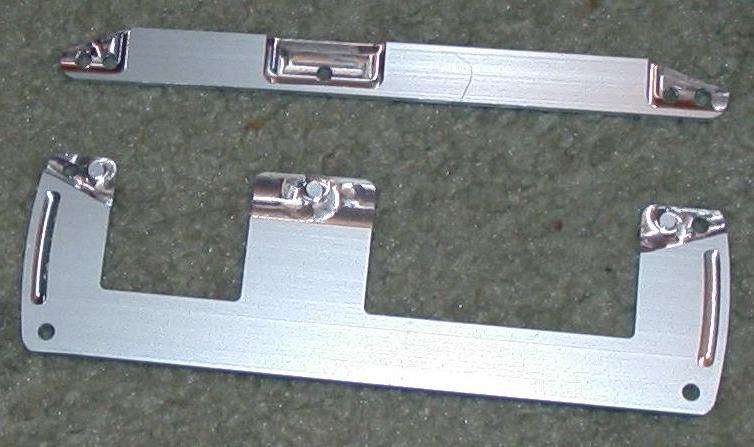

Simple endplate and OLD, OBSOLETE frontplate :

- We also want to manufacture endplate, but that is really simple when the frontplate is designed. it's just one peace, without the windows for the connectors. The gasket-notch is still there on the endplate too, not seen on the picture because it is on the other side.

- We do NOT want to manufacture the old frontplate design, because having the screws in the overlapping section is really nice

TODO:

- simplify the design: machine time should be decreased. See below.

- relocate manufacturing to (near) Budapest, Hungary (we need a reliable still cost efficient partner)

- organized repository of CAD files (maybe in restricted repository)

Simplify design

- we apply a 2 dimensions design: using 2 levels: drillthrough (and boundaries) and overlap section (and the third is the not-machines full 3mm)

- We want to drop the keying. The 2 screws will be just enough. No nead for it to withstand nuclear catastrophes.

- the overlap at the middle section should be small (3..4 mm). I suggest 4 turns, 135 degrees each.

- the overlap at the corner should be small (3..5 mm - the hole must be in the overlap, fully). But remember: no aligning sticks... 135 degree turns preferred here too.

- do we want a VEMS text somewhere ?

- do we want DB15 hole on some endplates ?

No need for these with the 2D machining:

- Radius should go up ++. Such sharp, small radius corners (where the boards meet) should not be needed. This will not be an issue because of the 2D machining

- the bigger radius should also apply to the seal-notch. Ideally the notch should be done with a big tool in one go. There is really no size-tolerance requirement for that notch (no sealing or other purpose, just to clear the aligning lobes of the alubos gasket). The notch will be V shaped with 2D machining.

- currently they are a little tight on the EC connectors (in all directions) and could use another 0.03 .. 0.1 mm clearance (otherwise they are hard to assemble and really hard to remove after installed). Some manual (drill and sandpaper) could work here to decrease width, and the adjust will happen automatically when the boundaries are adjusted for 2D manufacturing. Especially if sanded in the end.

Surface finish - optional

options:

- sanding

- eloxizing (cool colors)

What format is needed to manufacture? - alternatively they can just redesign, given the pictures, files, Alubos and connectors.

- they couldn't use the .MC9 files (are they specific to an environment?)

- mc9 == mastercam version 9

I can export but it take some work on the import it seems that inporting/exporting from one CAD to the next seems to always need some work.

The HU countryside (unreliable partner) shop could use

BUT THIS IS NOT GOOD FOR NOWRequired format: we need this for now:

- Coreldraw or

- EPS encapsulated postsript: with different colors (preferred) or different files for layers.

The 2 part frontplate must be in 2 different files (especially if it is EPS). One better be mirrored so the same sheet-laying and tool-mounting logic applies. The height must be specified as extra input: simple in this case: the mid-height is 1.48 mm (total is 3.00 mm, but 2*1.5 mm will be somewhat > 3.00 when put one onto the other).

Don't worry too much: we will adjust the edges, especially at the overlapping section after the test-run. I think the edge of the overlap section when going from half to full height will be angled so a faster tool can be chosen: so the boundary will have to be offsetted a bit unless the edge refers to the mid-height (which it should, IMHO, so probably no worries).

Measurements in mm

Plexi version's division1 (all referenced from ECxx top edge):

-16, 21 (EC.. window), 36 mm

(just 1 mm lower than on [this pic], which is -15, 21, 37mm. The truth should be somewhere midway: -15.5, 21, 36.5 mm although if it's higher, the EC can be raised without much problem.)

division2 (all referenced from left drill):

13.0 (EC18 window), 45.9 , 76.0, (EC36 window) 138.9 , 153 (right drill)

the side is not straight but a parabola: climbs 4 mm on +-24mm:

4 = y = 1 / 144 * x * x = 1 / 144 * 24 * 24

Radius at EC36 and EC18 top: 2mm

Radius at corners: 5..7 mm

The above data is enough to make it's size match. The rest is free to size. Please verify.

Latest frontplate design - 2004.Nov