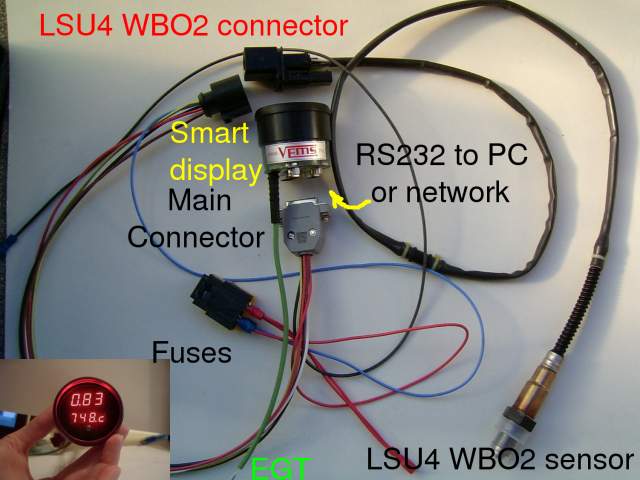

Smart-Round-Dual was the

The manufactured version:

Features:

- 3 digit 7 segment LED (with dots)

- 4 digit 7 segment LED (with dots)

- Voltage output. High resolution (up to 5V, 12bit, programmable output curve)

- RS232 level

- directly plugs into PC

- or USB-RS232 adapter

- or small dongle for CAN-physical layer bus (will not need to be removed from network even for firmware reflash!)

- free outputs

- power

- signal level

- extra inputs

- analog input

- RPM input

- button

Firmware features

Since this is ment as an easy-to-use device, first only very few features are supported.

- WBO2

- EGT (with cold-junction measurement)

- onboard-temp

- Data can be logged to PC for further analysis

Some pins suggest boostcontrol function. Note that (although possible, the hardware supports it at the same time as WBO2 and EGT) there is no boostcontrol firmware code for it now.

RPM input (VR or HALL, several trigger-types) will be supported later, eg. for logging or boost-target (currently not).

Pinout

RS232 (standard DSUB9 female, pin2,3,5)

- RX

- TX

- GND

Main connector - DSUB15 male

- 1: Vout (voltage output signal +)

- 2: WBO2 pump-

- 3: WBO2 nernst

- 4: WBO2 pump+

- 5: WBO2 Rcal

- 6: VBatt+ (12V)

- 7: WBO2 heater-

- 8: analog input

- 9: Vout-gndref (voltage output signal) -. Connect to GND or max 2..5V potential (with higher voltage on this pin, max output voltage on Vout will be limited).

- 10: RPM input

- 11: RPM reference (input threshold can be adjusted; leave open)

- 12: boost solenoid output (or other power output) max 5A, flyback towards supply

- 13: GND connect all GND-s

- 14: GND connect all GND-s

- 15: GND connect all GND-s

OLD stuff ... TODO: cleanup

The AfreshTiny was the working name for our first round 52mm WBo2 meter design.

Same circuit can also be used for other functions, see AfreshTiny/OtherUses

Input from user

- How do we do the free air calibration? At all? (would be nice)

- How do we choose between Lambda and AFR display?'''

- How do we choose vout curve?

- Will there be a datalogging output?

many devices rely upon some magic:

- BootLoader, ( harddrives, GM standard procedure to send engine error code via the CEL etc..) examines if 2 (production signal, or only for this purpose = jumper) pin is connected at powerup

- jumper or signal dedicated just for this

- we could have an optical port (maybe just simple phototransistor; but it's hard to make a solution that costs little footprint and is really useful), that could be used for this kind of magic:

- morseing input from the user

- maybe accept input from some standard IR remote control (apropriate firmware needed)

- optionally from PC (eg. from parallel port). This could make it possible to upgrade firmware too. If we keep the programmng connector accessible after filling with epoxy I think that this is the best option. This could also be used for jumpers.-Jörgen good enough...

Which ones do we need:

- Industry standard, 0.65v@lambda=0.65, 1.5v@Lambda=1.5

- NB sensor simulator, LSM11 reference curve.

- Autronic standard, 0-1v= AFR10-30

- wbo2.com 0..5V: 2.08V best power, 2.5V stoich You must be kidding?! No. Anything that has the diy_wb input can use a NB vout curve instead, but the NB curve does not have the same information as the WB. However I have no idea which signal standard is used where, and especially how widespread it is

- 0-5v linear output, who use this?

How do we change filter frequency for vout? (elaborate, please: why do we need to change ? )

It's important when using it with other aftermarket systems, sometimes you want it almost unfiltered and sometimes you want it as slow as 1Hz.

3x7 segment LED display

if possible, choose from:

common anode is more common.I ordered some 3x7 segment LED display samples from my local dealer:

- 9 mm tall segments, SMD (somewhat more expensive than throughole, but if it's better...)

- 14mm tall segments bright-green: the unit is 37.6 x 19 x 8.1 mm (pretty nice !!)

For the LED display I think that we should stay with hole mount since this allow us to fit components under the LED. On the other hand the SMD display won't waste space on the bottom of the board. The 14mm display look compatible with the one I have used for the board. -Jörgen

Available colors:

Red, yellow, green, Superbright red.

fuse would be nice:

http://www.elfa.se/elfa-bin/setpage.pl?http://www.elfa.se/elfa-bin/dyndok.pl?vat=0&dok=2013574.htm

However this fuseholder prevents us from making the whole unit in a size of 17mm tall, 52 mm diameter "cake".

Crystal

- I think the 1-board unit can do without a crystal (max 8 MHz?). Lacking extra IO, is limited to WBO2 anyway.

- The 2 board controller needs (and has) a crystal. Sly says we could look at digikey for smaller crystal if we want more space.

http://www.citizencrystal.com/quartz/crystals/cs10_d.htm

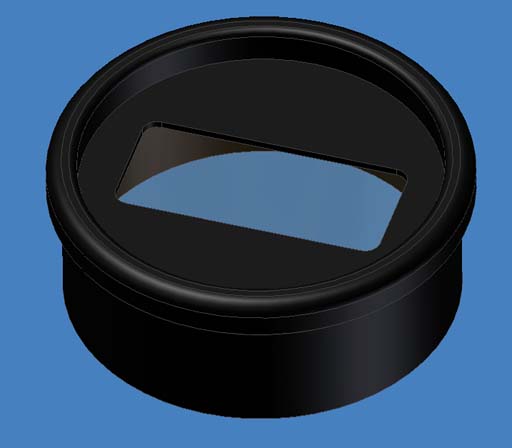

This is a model of the new enclosure:

What would be the price for complete assembled unit?

- 52 mm dia, 18 mm tall, 1 board: 198 Euro including sensor

- 52 mm dia, 40 mm tall, powerful (2 boards inside, this can do boost, ignition, injection and all nice stuff) : 298 Euro including sensor

Both would have flying loom and connector