The AfreshTiny is the working name for our round 52mm WBo2 meter.

Same circuit can also be used for other functions, see AfreshTiny/OtherUses

There is a two board version that probably won't be manufactured.

The single board AfreshMicro will replace it:

Features:

- I propose 0603 components (resistors and small caps) - I would say use 402 they are still easy to put on by hand if needed.

- 3 digit 7 segment LED

- Voltage output. 8 bit in HW (??) but thats practically any resolution with softpwm.

- why are we using the large LM324D? The TSSOP is a lot smaller... Correct me but many nice OPA is only SOIC, eg. [these from texas]

- no buttons. Free-air calibration can be triggered if the sensor is connected after powerup. I don't know yet if this suggests some new HW feature or pure software is sufficient.

To allow plugnplay calibration with the Rcal there are 2 options:

- expensive, hard (impossible?) to get OPA,

- or board temperature measurement and calibration (during the testing process). The small NTC would be nice.

Locking:

unlocked afreshmicro_r025_jk

added a lot more ground and made Gerbers

cleaned up sch so it is more readable

.cmp==top

.sol==bottom

.stc==top mask

.sts==bottom mask

.drd==drill file

.dri==drill info file

.drl==drill tool rack

Todo:

- onboard NTC

- should we edit the avr libary it looks like the pads are too thick. From the v3.2 quality it looks like the PCB house can do 4 mil, but they claim 6mil. I recommend design to 8..10 mil and going 7 where needed.

- Check sch for errors

- a second pair of eyes checking DRC's.

- Create Gerbers.

- Come up with a way to protect the ISP connector during the casting process.

Cast the flying lead into the epoxy.

Use female headers.''

- Solve ISP connector problem.

History:

- Make new crystal component and fit it. -done

- Make new fuse footprint and update board with it. -Done

- Decide if we want to use the Citizen crystal. - Done!!! We NEED the citizen crystal.

- Make good analog supply -Done!!! Good enough...

- Decide if these 'digital transistors' is available, they let us remove 8+3+3 resistors from the board!!! We won't need the 1206 sized Rnets if we use these. NPN: http://www.elfa.se/pdf/71/07100720.pdf PNP: http://www.elfa.se/pdf/71/07100738.pdf 7 euro for 100 units in 100Q. Done!!! We had to use them. - More of them here: http://dkc3.digikey.com/PDF/T043/0628.pdf

- Pick and add fuseholder that can be cast into the epoxy cake.

- http://dkc3.digikey.com/PDF/T043/1060.pdf, LittelFuse Vertical Mount mini ATO fuseholder, the vertical one, figure 2 -Done!!! http://www.littelfuse.com/data/Product_Catalogs/Chapter13Fuseholders.pdf, p15 shows technical drawing from the manf www.littelfuse.com

- Add SMD transient diode -Done

- Convert to Common Anode display (currently Common cathode display) -Done

- Map LED lines to the MCU -Done

- Add more items to this list.

Important

LED power input protection:

- By measuring the vbatt voltage we know if there is an alternator surge, we simply turn the leds off over a certain VBATT.

- The transistors protect against reverse polarity. Right? No, I think they don't protect. Don't they work as a diode in the backward direction?-Jörgen No.

- Do we need a better voltage reference then the L7805? No, we can store device calibration data in flash and / or EEPROM. But this is an extra step during assembly, wouldn't it be worth half an Euro per board to avoid having to calibrate them?-Jörgen I don't see how it would decrease the number of steps, as the whole unit requires testing anyway, and the testing reveals these calibration automatically.

Input from user

- How do we do the free air calibration? At all? (would be nice)

- How do we choose between Lambda and AFR display?'''

- How do we choose vout curve?

- Will there be a datalogging output?

many devices rely upon some magic:

- BootLoader, ( harddrives, GM standard procedure to send engine error code via the CEL etc..) examines if 2 (production signal, or only for this purpose = jumper) pin is connected at powerup

- jumper or signal dedicated just for this

- we could have an optical port (maybe just simple phototransistor; but it's hard to make a solution that costs little footprint and is really useful), that could be used for this kind of magic:

- morseing input from the user

- maybe accept input from some standard IR remote control (apropriate firmware needed)

- optionally from PC (eg. from parallel port). This could make it possible to upgrade firmware too. If we keep the programmng connector accessible after filling with epoxy I think that this is the best option. This could also be used for jumpers.-Jörgen good enough...

Which ones do we need:

- Industry standard, 0.65v@lambda=0.65, 1.5v@Lambda=1.5

- NB sensor simulator, LSM11 reference curve.

- Autronic standard, 0-1v= AFR10-30

- wbo2.com 0..5V: 2.08V best power, 2.5V stoich You must be kidding?! No. Anything that has the diy_wb input can use a NB vout curve instead, but the NB curve does not have the same information as the WB. However I have no idea which signal standard is used where, and especially how widespread it is

- 0-5v linear output, who use this?

How do we change filter frequency for vout? (elaborate, please: why do we need to change ? )

It's important when using it with other aftermarket systems, sometimes you want it almost unfiltered and sometimes you want it as slow as 1Hz.

3x7 segment LED display

if possible, choose from:

common anode is more common.I ordered some 3x7 segment LED display samples from my local dealer:

- 9 mm tall segments, SMD (somewhat more expensive than throughole, but if it's better...)

- 14mm tall segments bright-green: the unit is 37.6 x 19 x 8.1 mm (pretty nice !!)

For the LED display I think that we should stay with hole mount since this allow us to fit components under the LED. On the other hand the SMD display won't waste space on the bottom of the board. The 14mm display look compatible with the one I have used for the board. -Jörgen

Available colors:

Red, yellow, green, Superbright red.

fuse would be nice:

http://www.elfa.se/elfa-bin/setpage.pl?http://www.elfa.se/elfa-bin/dyndok.pl?vat=0&dok=2013574.htm

However this fuseholder prevents us from making the whole unit in a size of 17mm tall, 52 mm diameter "cake".

Crystal

- I think the 1-board unit can do without a crystal (max 8 MHz?). Lacking extra IO, is limited to WBO2 anyway.

- The 2 board controller needs (and has) a crystal. Sly says we could look at digikey for smaller crystal if we want more space.

http://www.citizencrystal.com/quartz/crystals/cs10_d.htm

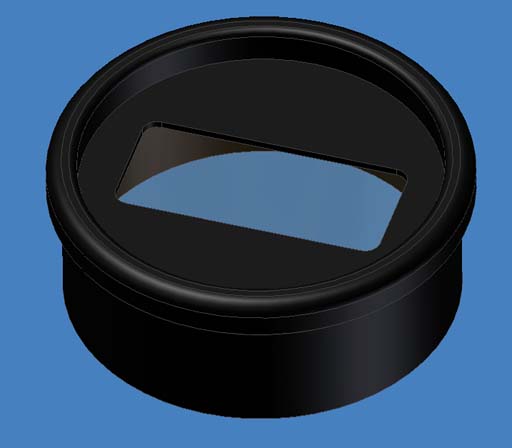

This is a model of the new enclosure:

What would be the price for complete assembled unit?

- 52 mm dia, 18 mm tall, 1 board: 198 Euro including sensor

- 52 mm dia, 40 mm tall, powerful (2 boards inside, this can do boost, ignition, injection and all nice stuff) : 298 Euro including sensor

Both would have flying loom and connector