Smart-Round-Dual was the

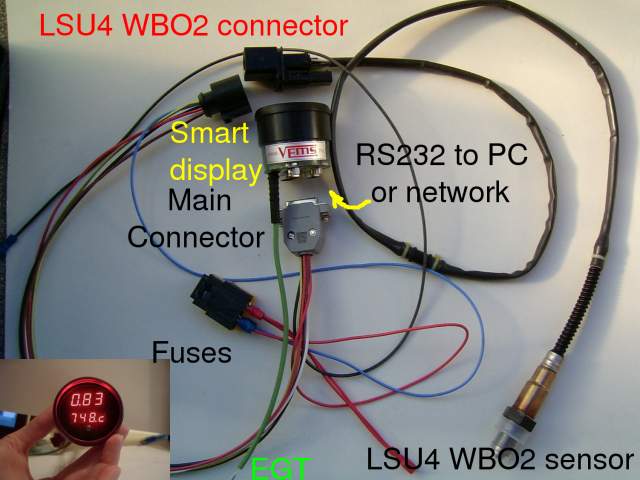

The manufactured version:

Features:

- 3 digit 7 segment LED (with dots)

- 4 digit 7 segment LED (with dots)

- Voltage output. High resolution (up to 5V, 12bit, programmable output curve)

- RS232 level

- directly plugs into PC

- or USB-RS232 adapter

- or small dongle for CAN-physical layer bus (will not need to be removed from network even for firmware reflash!)

- free outputs

- power

- signal level (0..5V high resolution, external ground referenced)

- extra inputs

- analog input

- RPM input, or vehicle-speed (kmh / mph) or other frequency signal

- button

Firmware features

Since this is ment as an easy-to-use device, first only very few features are supported.

- WBO2. Lambda value matches Bosch (manufacturer of the LSU4 sensor) specifications. Tested against very expensive 6-gas analyzers (with 2 - different - sensors in same exhaust stream) with very good match (showing 0.86 / 0.87 when the high-end analyzer displayed 0.86 lambda)

- EGT (with cold-junction measurement)

- null-offset calibration (egt_cal, mttg01mttc.. where replace .. with hexa number: C0 is default, 00 is maximum subtracted offset, 96C)

- onboard-temp

- Data can be logged to PC for further analysis

Some pins suggest boostcontrol function. Note that (although possible, the hardware supports it at the same time as WBO2 and EGT) there is no boostcontrol firmware code for it now.

RPM input (VR or HALL, several trigger-types) will be supported in firmware later (currently not), eg.

RPM is scheduled to be available in firmware in 1 month. I recommend to wait if you don't need the unit right now and know you'll need RPM ( though it should be a firmware-only change, the input voltage levels will be calibrated later in production making it easier to use )

- for logging

- or (RPM-dependent) boost-target

- or vehicle-speed sensor data can be sent over the network to GenBoard/VerThree even when both primary and secondary VR inputs of the v3.x are used up for the engine (the vehicle-speed and fuel consumption can be displayed and logged; also allows much better street-dyno implementation than without vehicle-speed)

Pinout

RS232 (standard DSUB9 female, pin2,3,5)

- RX

- TX

- GND

Main connector - DSUB15 male. Note that the (now standard) flying loom version has the WBO2 pins on the WBO2 connector, so those 5 pins (pin 2,3,4,5 and 7) of the DSUB15 are NOT connected:

- 1: Vout (voltage output signal +)

- 2: WBO2 pump- (Sensor pin 5)

- 3: WBO2 nernst (Sensor pin 1)

- 4: WBO2 pump+ (Sensor pin 6)

- 5: WBO2 Rcal (Sensor pin 2)

- 6: VBatt+ (12V)

- 7: WBO2 heater-(Sensor pin 4)

- 8: analog input

- 9: Vout-gndref (voltage output signal) -. Connect to GND or max 2..5V potential (with higher voltage on this pin, max output voltage on Vout will be limited).

- 10: RPM input

- 11: RPM reference (input threshold can be adjusted; leave open)

- 12: boost solenoid output (or other power output) max 5A, flyback towards supply

- 13: GND connect all GND-s

- 14: GND connect all GND-s

- 15: GND connect all GND-s

- Also wire supply voltage to WBO2 Heater to sensor pin 3 through 5A fuse (this is wired this way in the supplied harness)

'Q' Which pin is the NBO2 output?

'A' Pin#1, Vout is the nbo2 voltage output (signal+ output), pin#9 Vout-gndref volt out - signal (connect to GND).

Mounting

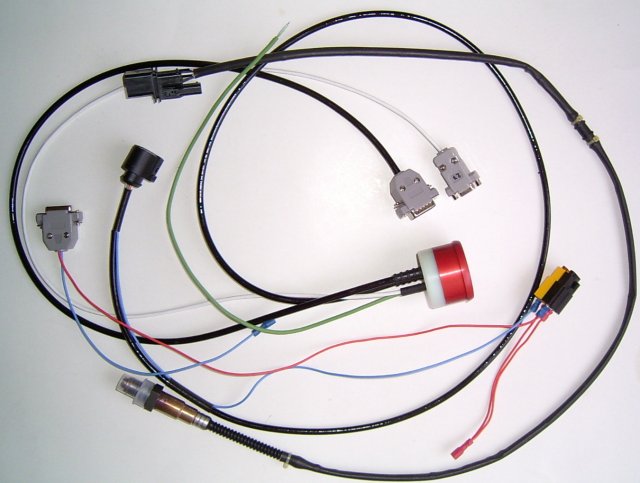

The flying loom version allows mounting even with the tightest available space:

The upcoming mounting style uses an U bracket:

This really is a professional product, now we need to get the marketing name right...

OLD stuff ... TODO: cleanup

The AfreshTiny was the working name for our first round 52mm WBo2 meter design.

Same circuit can also be used for other functions, see AfreshTiny/OtherUses

Input from user

- How do we trigger the free air calibration? At all? (would be nice)

- How do we choose between Lambda and AFR display? (or Celsius/Fahrenheit)

- How do we choose vout curve without RS232 ?

- How to insert "markpoints" in the datalog

Because of the

- analog inputs

- button

- network connection

this is a software issue.

Which ones do we need ? HW output (high vout resolution) allows either:

Linear WBO2 lambda output

Useful with ECU-s that has no embedded WBO2 controller, but can accept linear WBO2 signal! Also useful if the other ECU has real WBO2 input but you don't want to use 2 WBO2 sensor.

This was tried with 3V/lambda wired in (connected to a motec). Included in next release in a configurable way (so either NBO2, or linear output can be selected with chosen n V / lambda ).

0V (well, say < 0.2V) used for unknown (eg. sensor not heated yet)

- 1V / lambda 0.65v@lambda=0.65, 1.5v@Lambda=1.5

- only when this is the only choice; or when viewing with a handheld DVM

- 3V / lambda was successfully tried with motec input. The input curve in Motec can be configured (allows 0..5V input range); vout_conf=99

- 4V / lambda : maximum practical (max 1.25 lambda limited by output range)

- 5V / lambda could be useful with -1.5V offset (0.6 lambda => 1.5 V ; 1.3 lambda => 5V). This would allow the best interfacing precision (although 3V / lambda is already very good).

NBO2 - implemented

- NB sensor simulator, LSM11 reference curve. This curve is mostly useful for old type NBO2 input equipped factory ECU-s only, since it has very low slope (=> hard to tune, prone to noise) at lambda=0.8 which is kindof unfortunate vout_conf=01

Special

- Autronic standard, 0-1v= AFR10-30

- using the near 0V part of the curve is very unfortunate (much better is 0V = error or unknown)

- 10 AFR (0.68 lambda) minimum is a bit unfortunate as well

- old diy style 0..5V: 2.08V best power, 2.5V stoich. (this is Ip based, vout_conf=02)

- Linear 0-5V EGT output (0V at -50C; 4mV/C, so 4.8V = 1150C). vout_conf=00 It could be also good usable with other ECU-s that can't accept the k-thermocouple signal directly.

Note: besides the vout curve, the vout filter frequency would be nice if adjustable (when using it with other aftermarket systems, sometimes you want it almost unfiltered and sometimes you want it as slow as 1Hz.)

Firmware upgrade - experimental release

- [RoundLoader_firmware01.zip] includes

- 2006-04-11 firmware, that supports RPM input

- roundloader_beta native win32 binary (roundloader.exe and bat files). You will need to adjust to your COMx port

- eg. replace COM3 => COM2 (or whatever applies).

- roundloader.exe -p COM3 -s 19200 -f C:\tmp\STABLE1_0\minrtest\round.chex -c write

- change C:\tmp\STABLE1_0\minrtest\round.chex to round.chex in the command (sorry, the absolute reference will be dropped in next release)

- start it from a "run -> cmd" shell, not by clicking on it so you see the output (success or error)

Please report any roundloader.exe problem (it seems fine, so success need not be reported from now)

- XP with pl2303 USB-RS232 adapter cable from WebShop: success

- Successfully upgraded/verified firmware with roundloader on WinXp sp2, notebook with USB/RS232 adapter. Seems fine. (MembersPage/GergelyLezsak)

- Successfully used roundloader to upload new firmware. Used on Dell D810 laptop on com 1. (Stefcross)

The oldschool method: prog.pl Works (similar to BootLoader) with new (included in the zip) prog.pl version (PERL and serialport module required). Prog.pl only recommended on linux, or if roundloader does not work for some reason. Ask for a linux roundloader native executable if you need it.

- Read the README file for display configuration

- (lambda/afr; Celsius/Fahrenheit; internal temp/EGT; soon RPM in upcoming release) through config.disp_state (also changed via button);

- comm.c if you want to improve MegaTune round.ini

- global.h if you want to improve MegaTune round.ini or configure manually through (Man)mttg..mttc..(mcs)(bye) commands

http://www.vems.hu/files/Firmware/Round/RoundFirmware00.zip (see the beta release below that has the same files included, along with other useful stuff such as megatune!)

Since the new firmware has many nice configurable features, unaware users can be tricked easily if not aware of the configuration. Damage to the controller device is extremely unlikely, but it's possible to damage the sensor with bad configuration.

Other beta software

- [beta release] of the MegaTune - TODO: more testing; this should stabilize in days

- log data the same way as with v3.x (megatune -> File -> Datalog)

- log analysis: vemslog viewer (or any LogAnalysis program that can take xls input)

- the shown EGT temp is 50C higher than real. 50C should be subtracted from the EGT and internal temp before display to compensate the offset, since minimal temp that can be logged is -50C (a one-liner round.ini change to be done in next release)

- [round logger v001] (needs .exe and dll's to startup properly, download into the same dir)

- unknown quality

- free air calibration

- the RCal resistor in the sensor is supported, so calibration is not necessary (it's not possible in current firmware release, although a new finetune config variable can be made for it if necessary). The optimal PID parameters are different in the exhaust stream and free air, so don't worry if free air reading is slightly off or even floating somewhat. Note that toleration in the lamdba range is very good: 5% error means (actual => reading) 0.8 => 0.81 lambda (since the difference from lambda=1.0 counts, which is 0.2 and 0.19 respectively).

- What is the timeframe for the BoostControl feature? //Nanassy Peter

- no good news here. There is no business decision on the standalone boostcontrol firmware-feature timeframe. A separate, (really) powerful boostcontroller (and logger, more featureful than many standalone ECMs) will be rolled in appr 2 months, which round can be used as a display for. It will be cheaper (like a bundle) for customers who also buy (or bought in the past) round.

RPM input

Devices shipped after 2006 March have the RPM input HW tested. (it's implemented from the start, but earlier it wasn't part of the testing.)

RPM input HW:

- rpm_input measures 5V if left open

- connect the signal input here

- rpm_gndref measures 2.5V if left open

- if the zero-crossing negative edge is to be detected (standard VR sensor, eg. typical magnetic wheel-speed sensor or 60-2 wheel), leave it open.

- if you want higher threshold, eg. for a 0V / 5V HALL sensor, connect rpm_gndref with a 220k pullup resistor to a 5V (or 510k to 12V)

Note: the pullup HW configuration will change in the near future (we'll update this) so HALL needs no pullup, and the VR needs pulldown to GND (not pullup).

RPM input config

- rpm_toothcount. The number of pulses per crank rotation.

- 02 for a 4 cyl 2 events per rotation

- 3a (decimal 58) for a 60-2 wheel

- or 23 (decimal 35) for a 35-1 wheel

- set with (Man)mttg19c.. like mttg19c02 or with MegaTune

- rpm_multiplier

- set with (Man)mttg1amttc.. like mttg1amttce5 or with MegaTune

- 229 - 0xe5 default for RPM display. Different value can be used to cheat, or for vehicle-speed.

The precision is 1 RPM. Note that display from 230 .. 15999 is possible. Above 9999 the first digit is hexa, so

- a845 (=10845 RPM)

- b231 (=11231 RPM)

- c000 (=12000 RPM)

- d888 (=13888 RPM)

- e792 (=14792 RPM)

- f999 (=15999 RPM)

- fffu (above 16000 RPM)

I need ASAP the following settings for Round

- Voltage output

- 0.1Volt at 0.75lambda

- 1Volt at 1.25lambda

This is a customer request,his external datalogger work with these settings.Please make it ASAP.My advice is _ make a custom pfree programmable output for this,just like innovate did,so every user can program his own desired linear characteristics.

The other way around would make much more sense:

- 0.55V at 1 lambda

- and decreasing: similar to NBO2 (but better slope)

and output sampling rate,

free programmable WOULD BE grat,

but i need 5 sample/sec

and 3 sample/sec.

4 samples / sec is OK ? Why is higher rate (that follows lambda more promptly) a problem ?Too much unusable data on datalogging,btw its a customer request.

"OK,lets try 4sample/sec.Is this the factory default sampling rate,or do i have to set it somewhere?"

"Please explain how RPM connection/configuration works.We want to connect the ECU (not vems) tachometer output"

//Nanassy Peter

Guide development here:

http://vems.hu/www.vems.co.uk/VEMSWB/UserGuide/readme.html

Need to know about a number of connection and configuration settings...